HydroFloat DAF

Standard Features

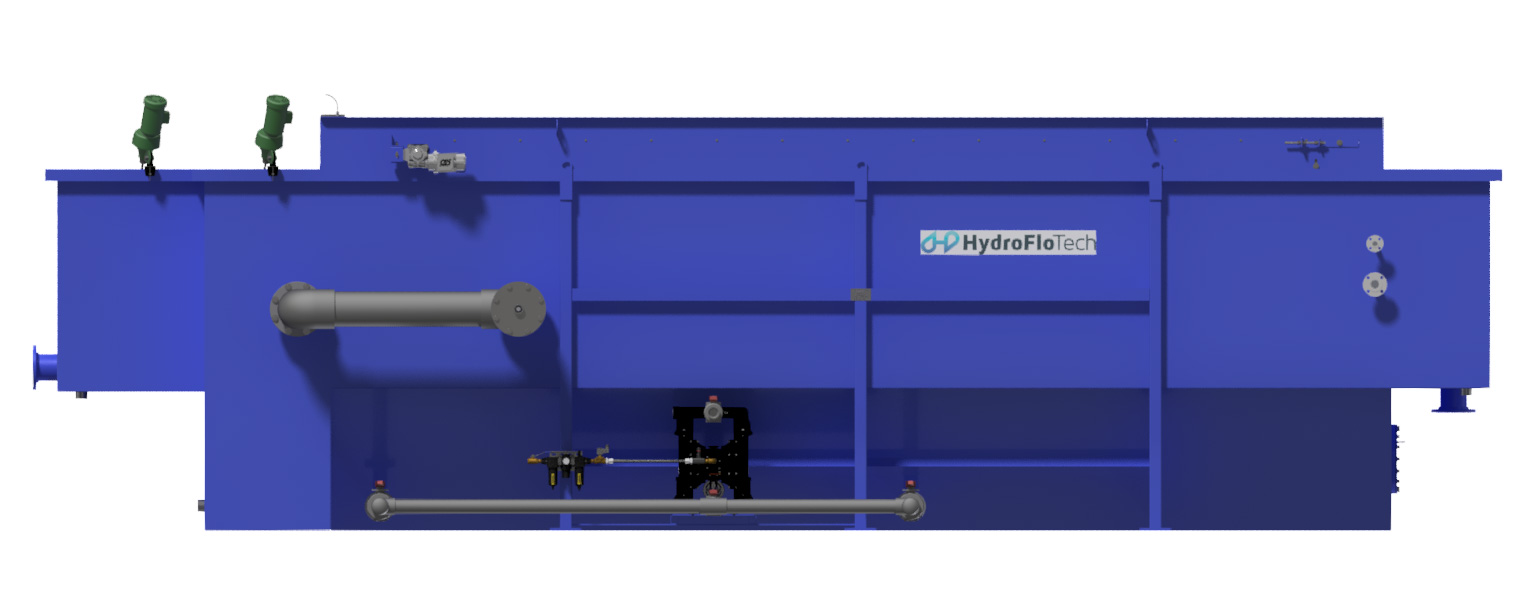

- Epoxy coated ASTM A-36 carbon steel tank

- API specified separation chamber

- Integral large capacity sludge reservoir

- Seamlessly integrates with other HydroFloTech wastewater products

Available Options

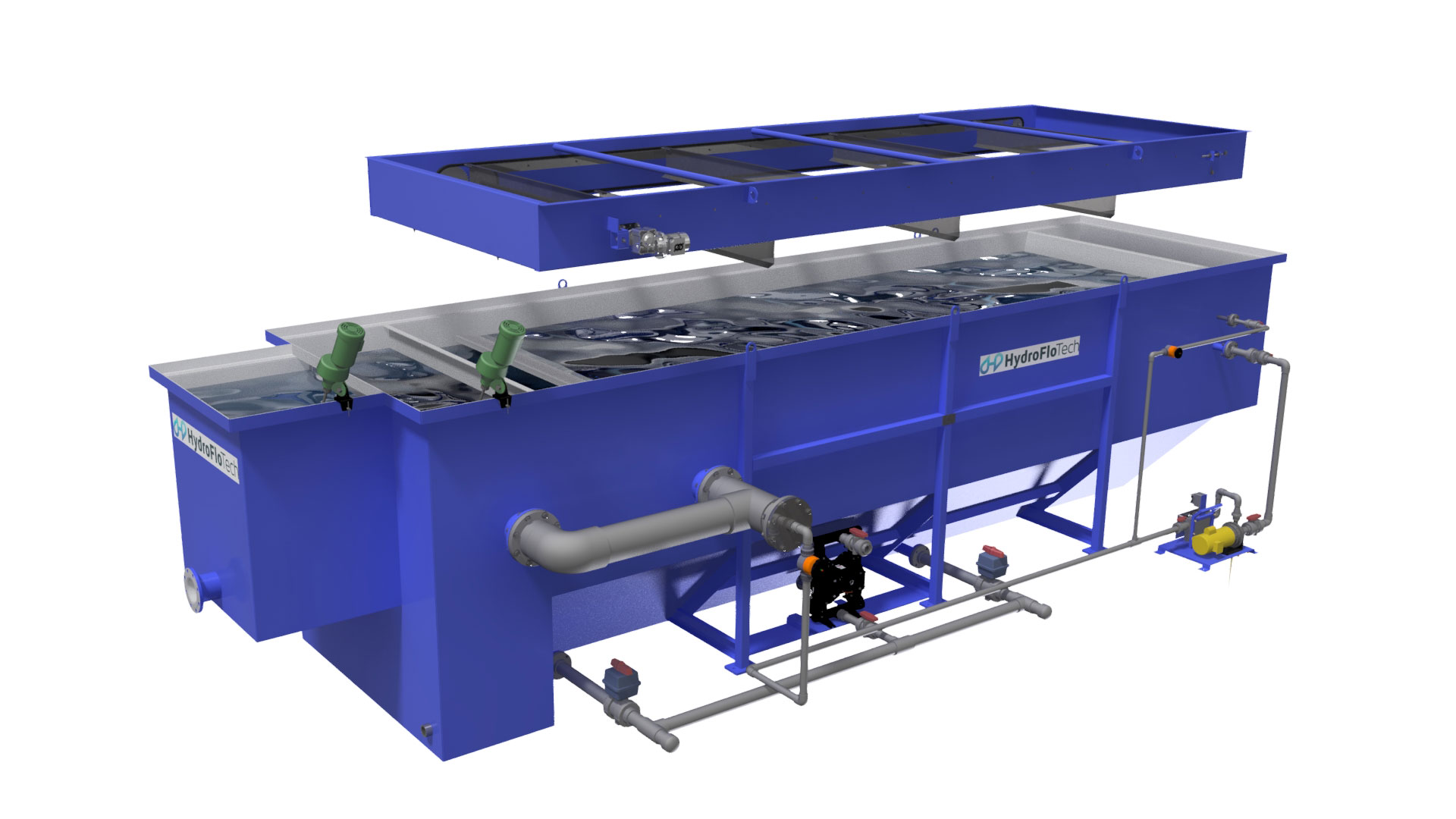

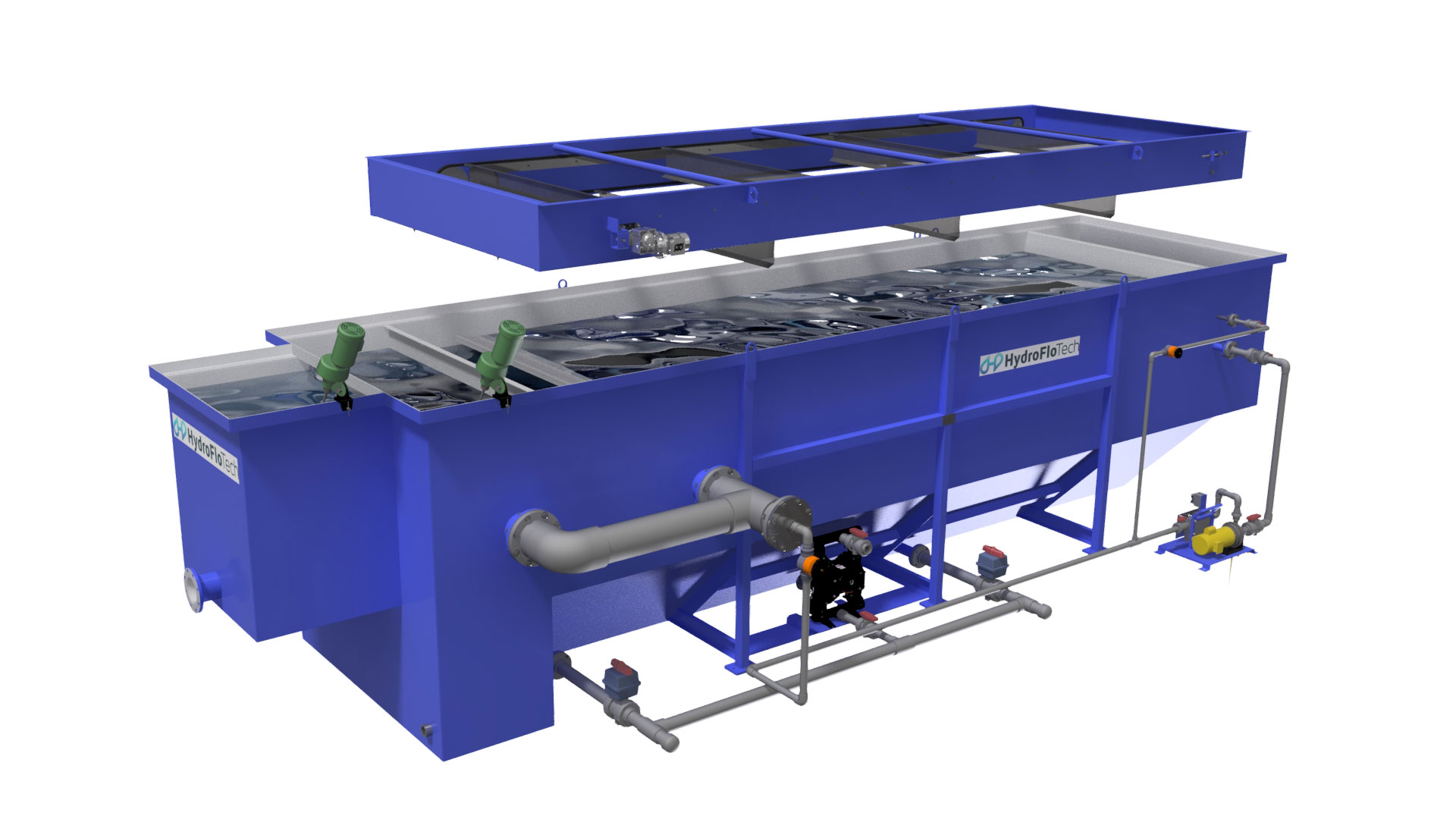

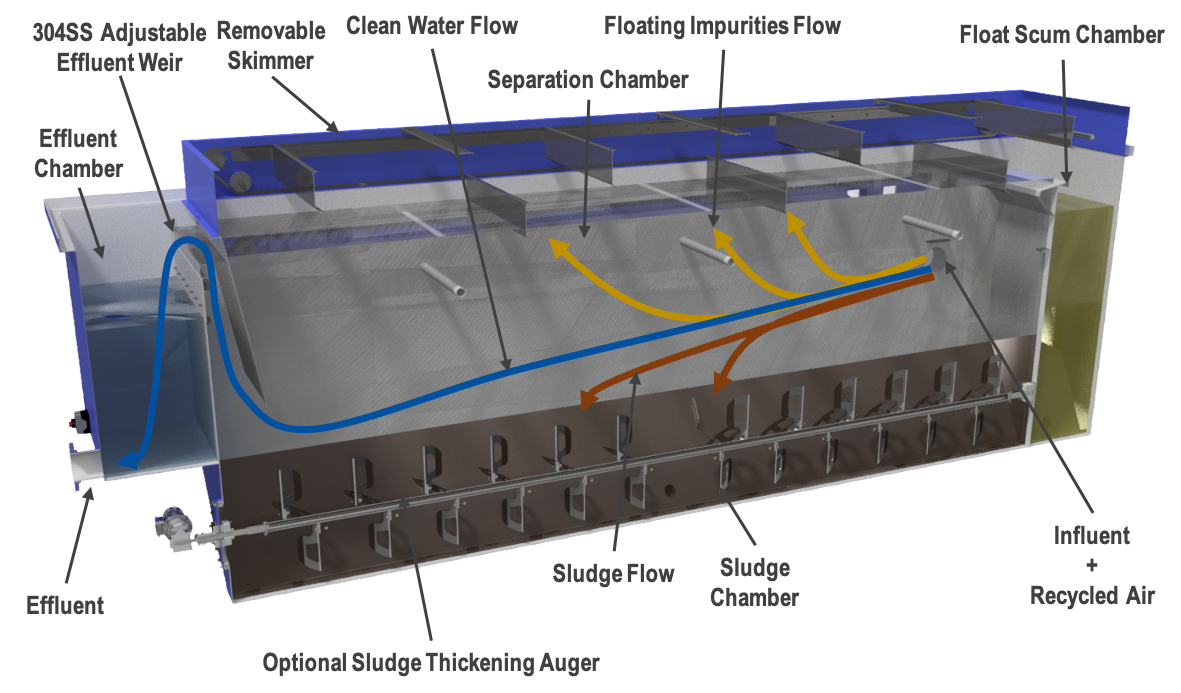

A dissolved air flotation (DAF) system resolves suspended solids and clarity issues by reintroducing a slip stream of treated water (from the system’s effluent) back to the system’s influent. This pressurized, recycled water is saturated with dissolved air. When the pressure is released at the system’s influent, the air comes out of solution on the surface of suspended solids particles throughout the dissolved air flotation (DAF) influent mixing chamber. As these billions of micro bubbles come out of solution, they float the suspended solids particle to the surface of the dissolved air flotation (DAF) separation chamber, where they are removed by a surface skimmer.

The HydroFlo DAF recirculation system is a micro bubble generator. A key factor for maximizing the efficiency of a DAF is the generation of equally sized micro bubbles. These bubbles, ranging from 10 to 50 microns in diameter, will give the suspended solids an equal and steady rise rate of 10 to 12 inches per minute, to the tank surface.

Our recirculation system is designed to completely saturate the recycle stream with air. By properly sizing our system (atomized water surface area, air dissolving rate, etc.) we can dissolve the maximum amount of air, physically possible, into the recycled water.

When the re-circulated flow reaches the DAF’s influent, it passes through a pressure release valve where it is released into the tank and allowed to return to normal atmospheric pressure. Fine micron bubbles spontaneously boil out of the recycled water solution.

As stated above, these billions of fine micron bubbles attach themselves to the suspended water particles in the wastewater, causing them to float to the tank surface where they form a firm surface sludge mat.

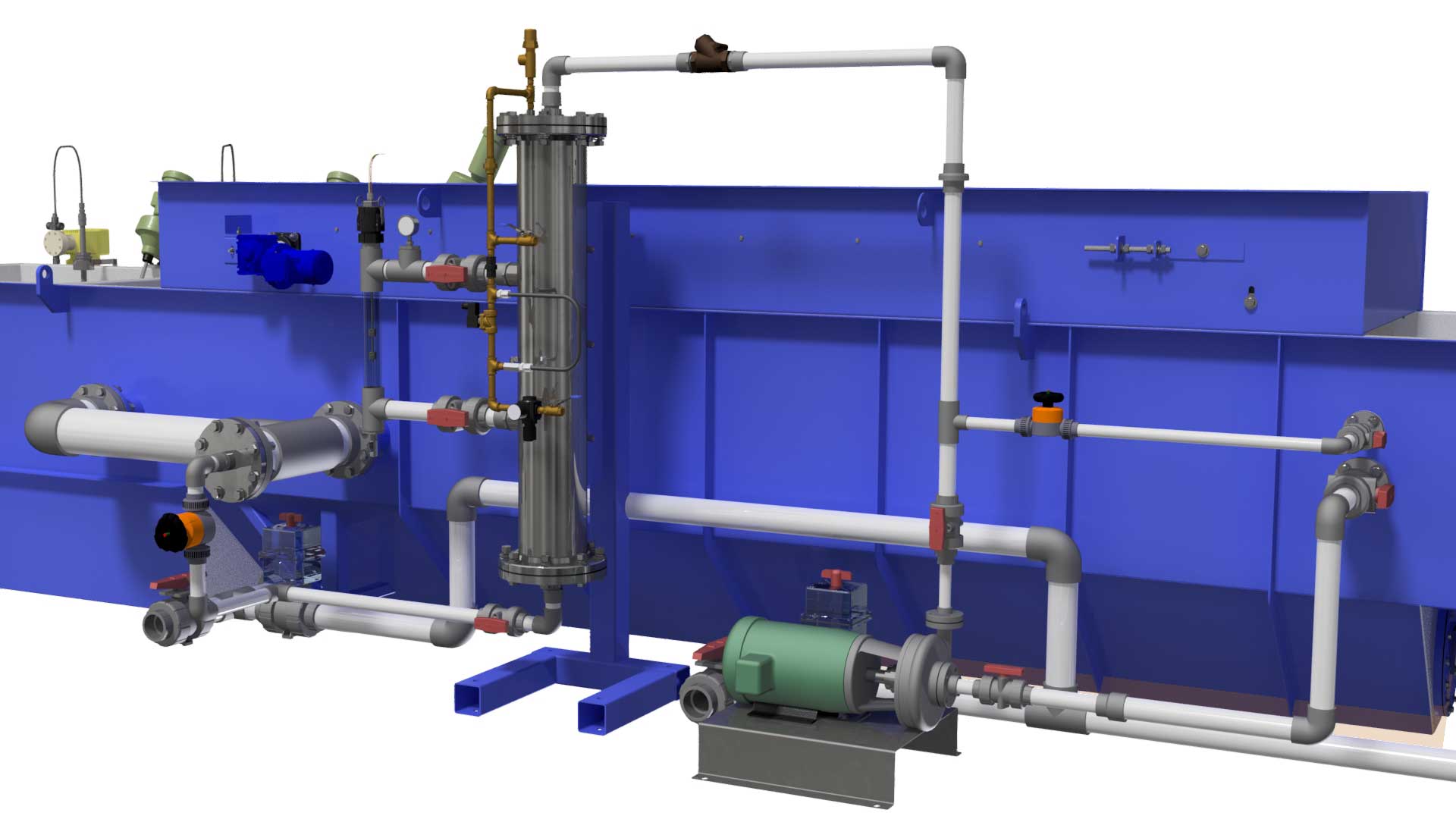

HydroFloTech manufactures complete dissolved air flotation (DAF) systems with recycle/air diffusion system including recycle pump, air saturation vessel and related controls. The DAF is sized to provide a surface loading rate equal to 3.0 lbs/ft2/hour of TSS and FOG combined. The HydroFlo dissolved air flotation system is designed to separate floatable particles of oil or solids by floating them to the surface with air bubbles. Our DAF system incorporates a high efficiency, high pressure air to water saturation contact recycle tank system, and a DAF separation cell with surface skimmer. The air bubbles form at the release of pressure and intimately contact the raw, incoming wastewater with a specially designed reaction nozzle system that promotes air bubble impingement with raw incoming wastewater particles and the forming air bubbles. The surface flight skimmer assembly drags the floated material to the skimming beach and into the float chamber.

DAF Separation Chamber:

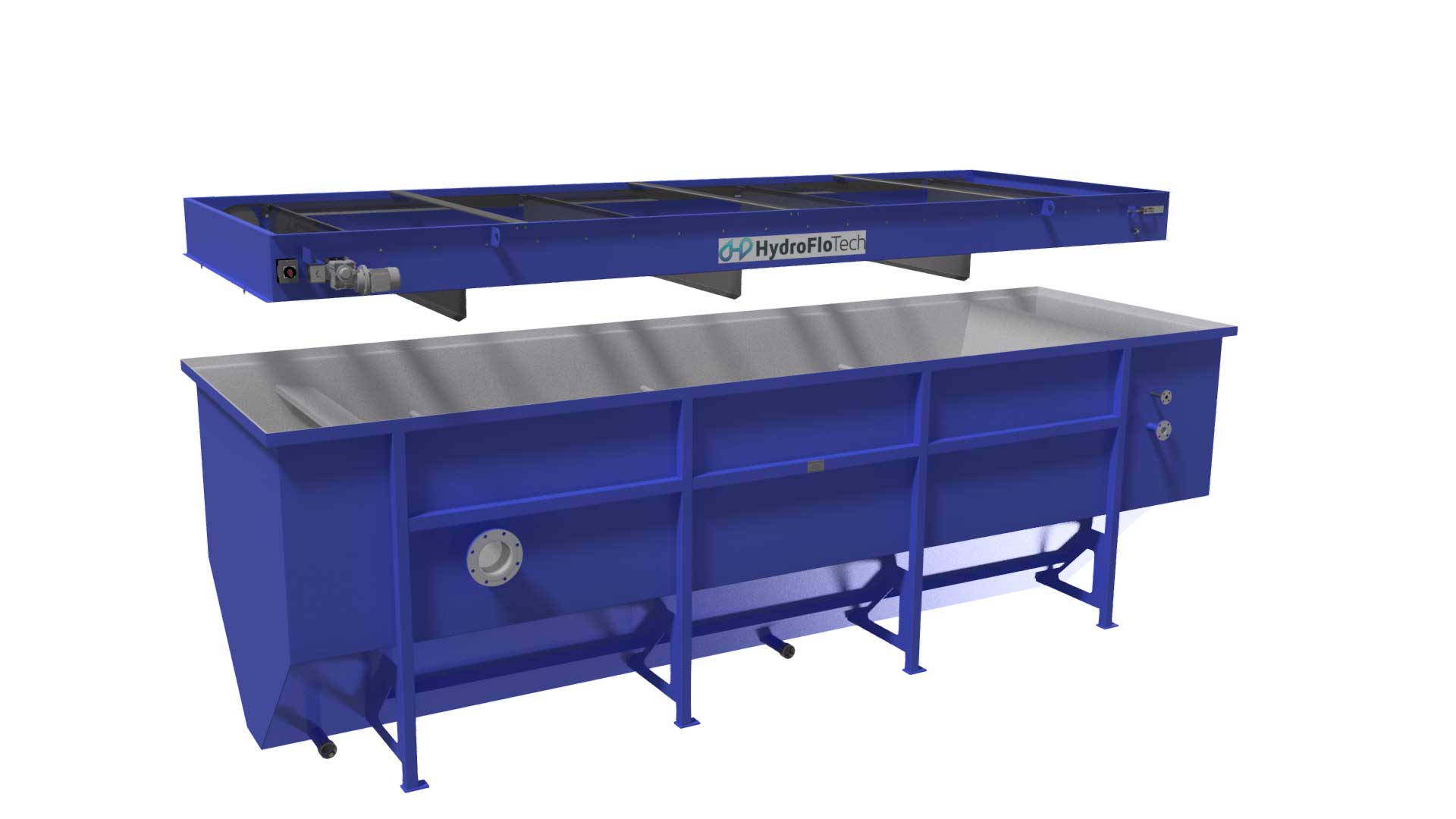

The DAF separation cell is designed using elements of American Petroleum Institute’s publication 421 Feb. 1990, “Design of Oil-Water Separators” to ensure the best possible use of particle rise rate performance. The separation cell can be fabricated with a flat bottom or a rectangular “V” bottom. The DAF cell is typically manufactured from carbon steel, but other materials of construction are available as an option.

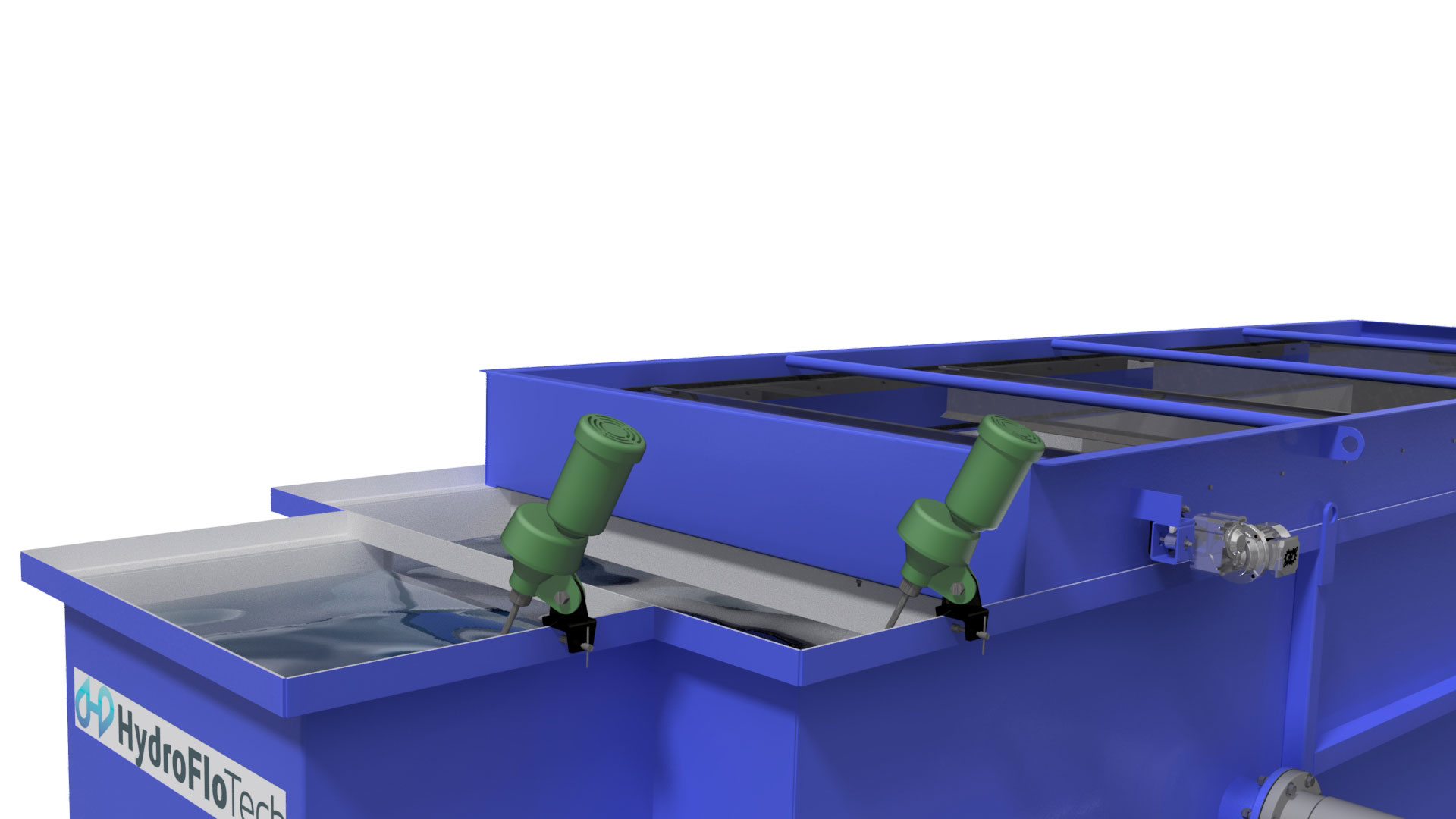

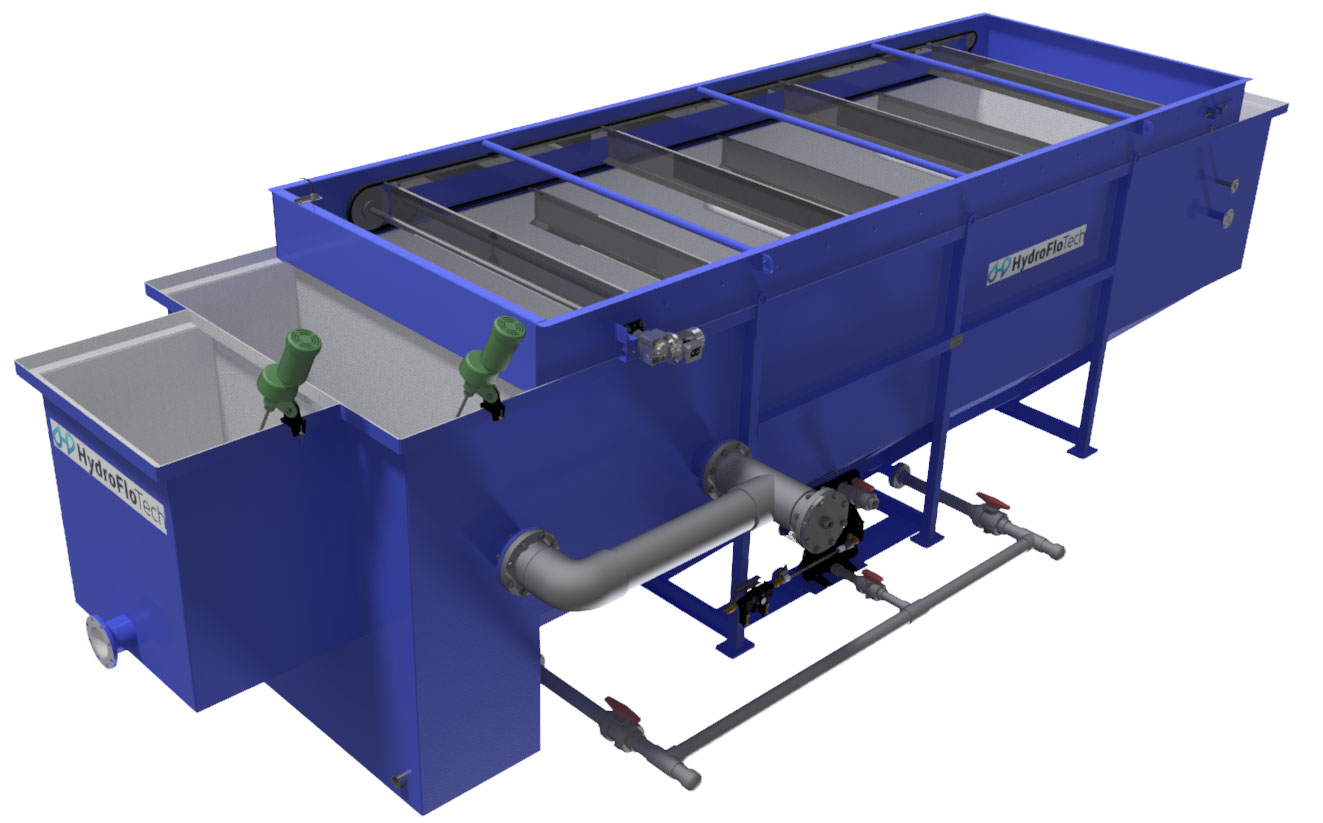

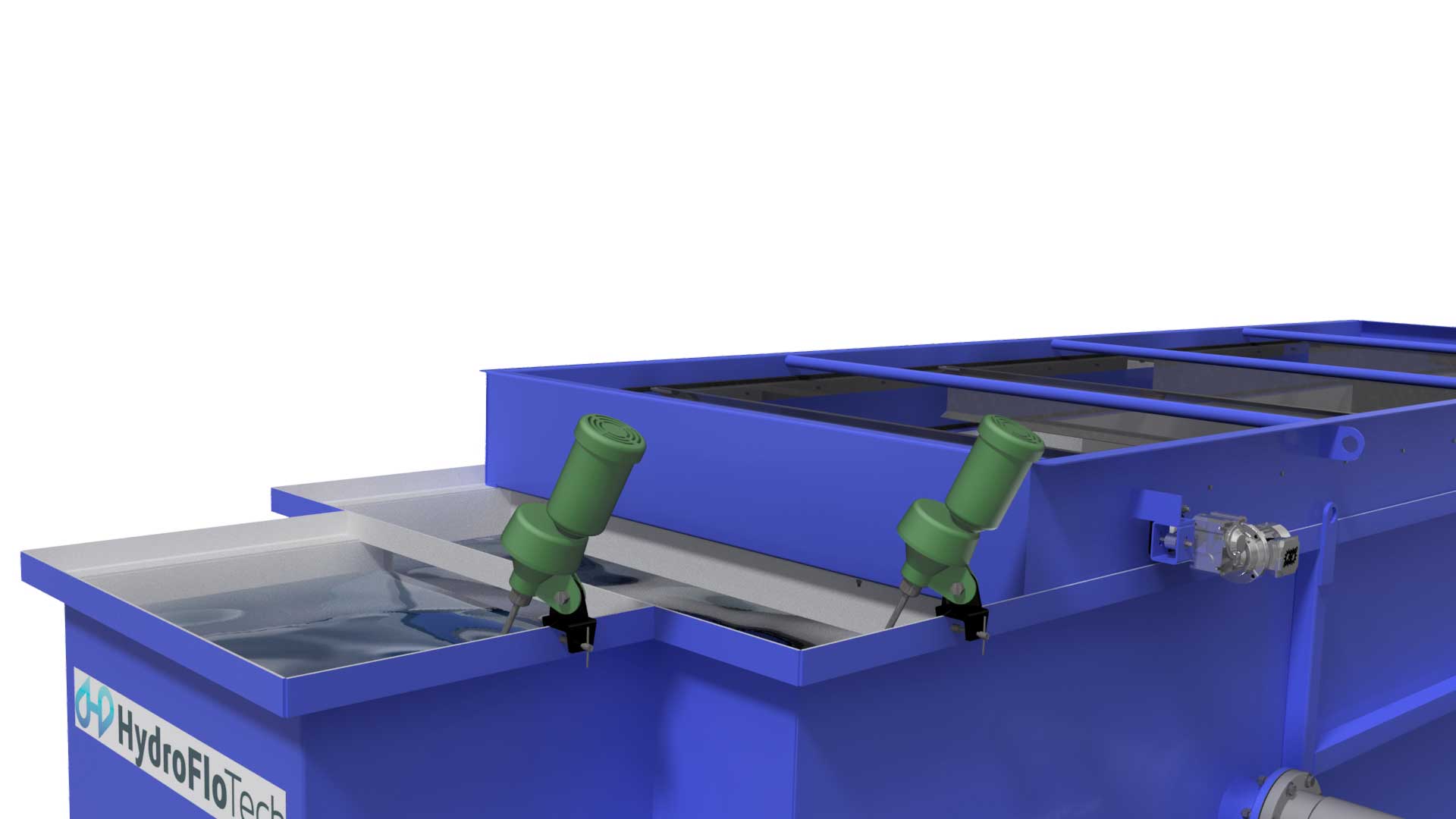

DAF Surface Skimmer:

HydroFlo provides a removable float skimming system with frame assembly and drive motor, sprockets, chains and full width stainless steel skimming blades. The skimmer blades are mounted on swivel pins that are fastened to the skimmer chains, which maintain the blades in a down position at all times. The conveyer chains are provided with drive sprockets on a full width shaft at the drive end and four independent idler sprockets at the return end. The skimmer system frame comes equipped with a sprocket tension adjustment device and the carrying and return tracks for the chain. The entire system is self supporting with side and end channels, and cross members with lifting lugs that permit removal of the skimmer assembly as a complete unit for easy cleaning and service. The skimmer drive system comes with a hollow shaft, maintenance free gear reducer. The skimmer system can be made vapor tight with the addition of optional cover panel.

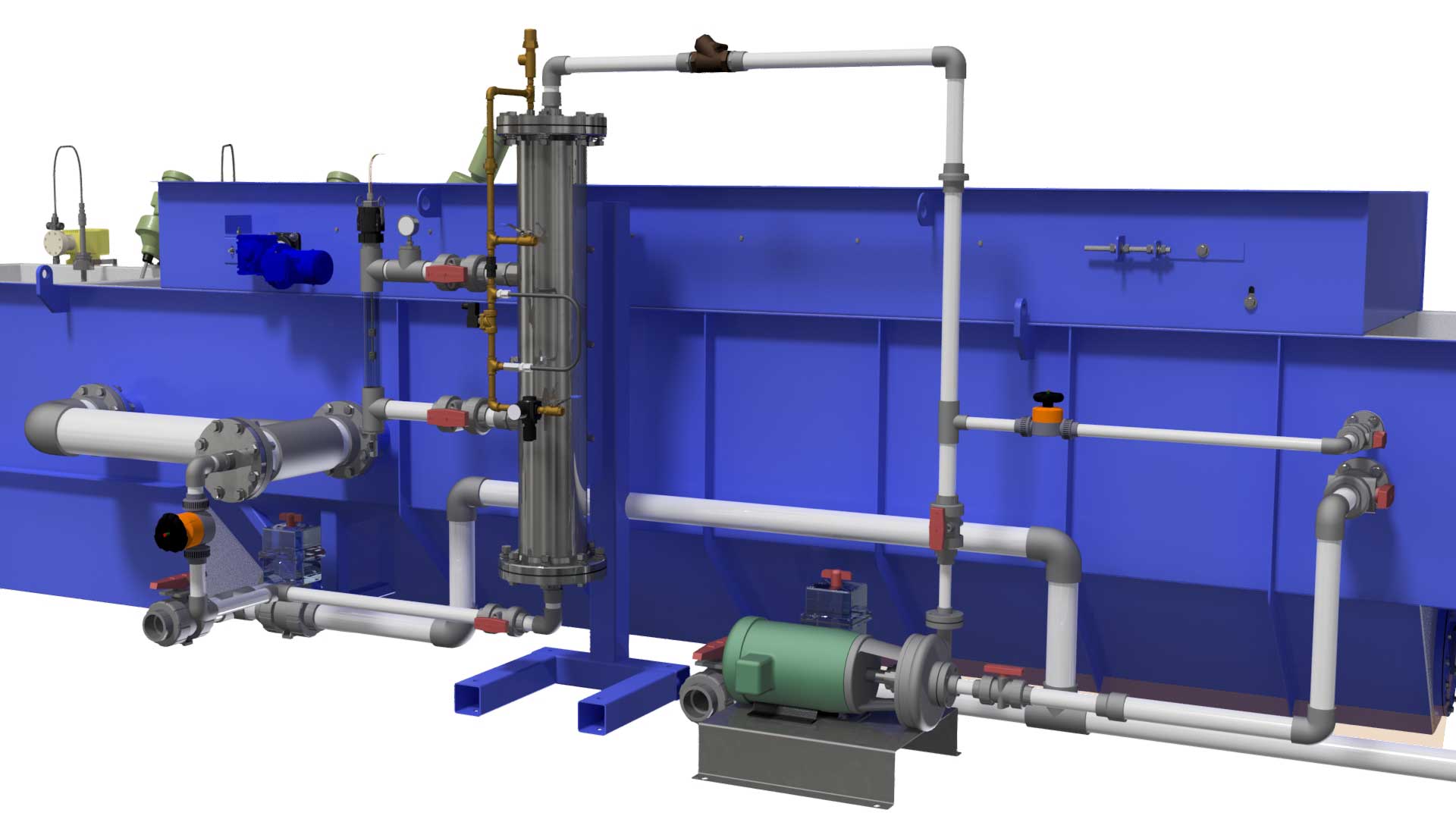

Air Introduction Systems: HydroFloTech specializes in two fundamental air introduction systems. Both systems are equally capable and may be chosen depending on client preferences.

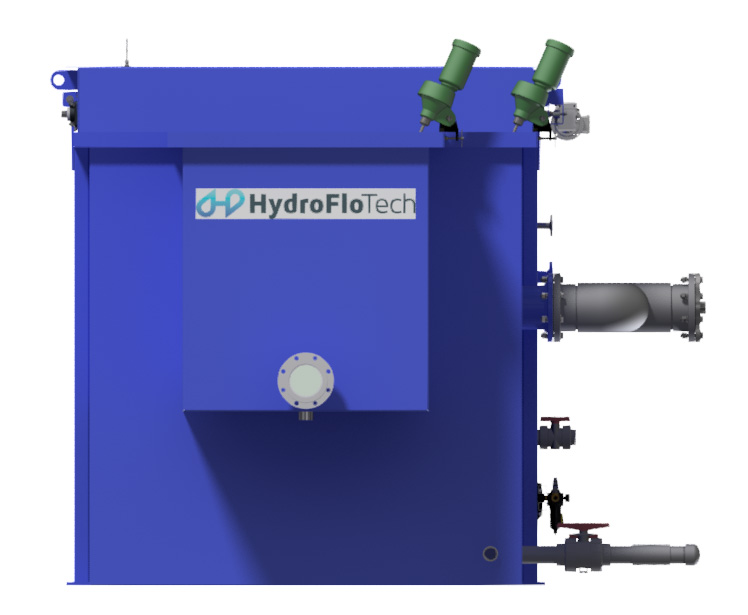

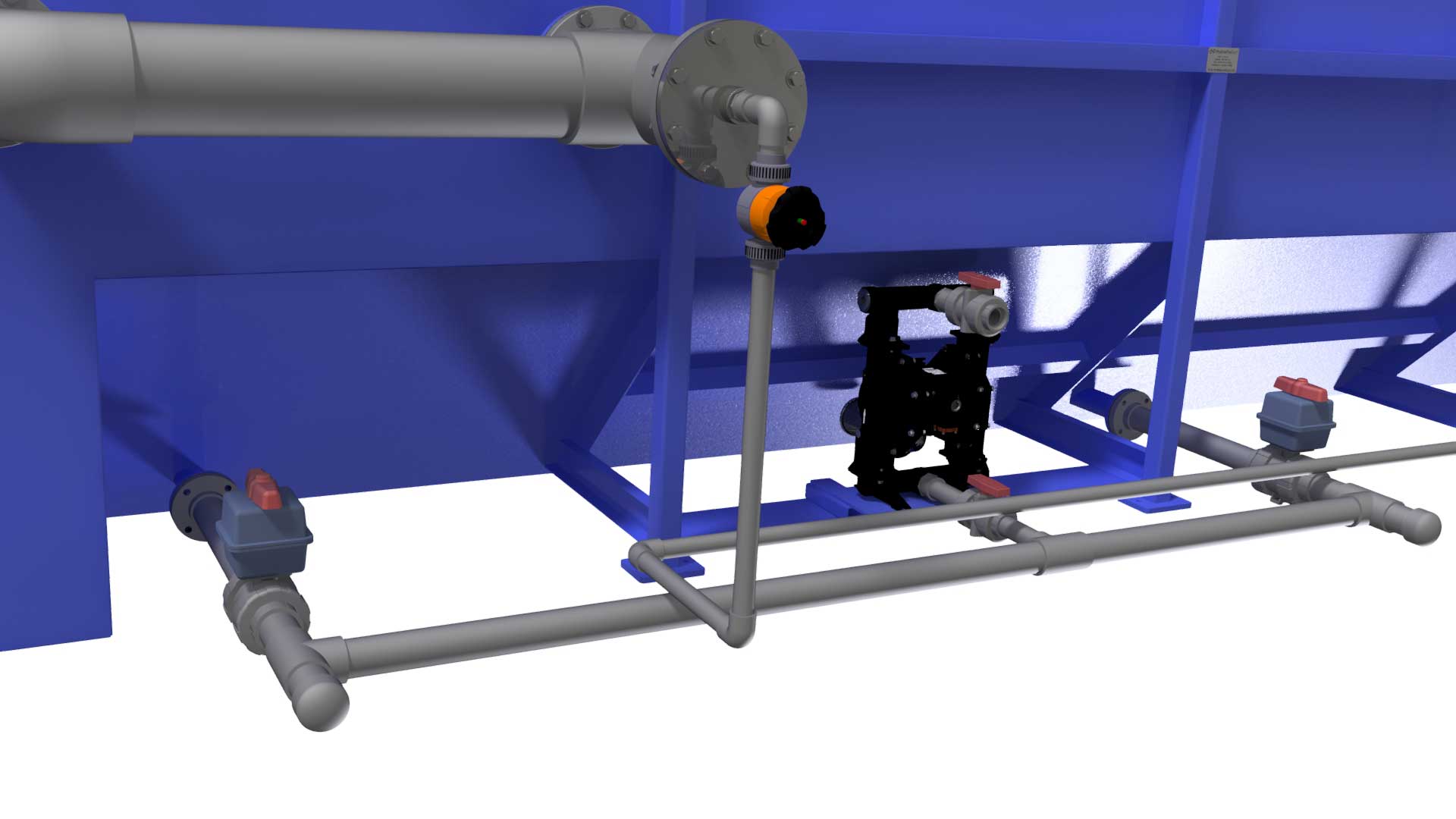

Option 1: Recycle / Air Dissolving System (RAD):

The HydroFloTech dissolved air flotation system comes standard with a recycle water air dissolving system rated at 50% of the DAF design flow, providing an air to solids ratio (A/S) of between 0.015 and 0.040 lbs air/lbs. solids. Standard models are designed for 100 psi, 100 degree F. The air dissolution tank is fitted with an internal water cascading nozzle system to ensure efficient mass transfer and air/water contact. The tank is provided with an independent safety pressure relief valve and pressure gauge. The air dissolution tank is provided with an external, clear sight tube with water/air interface level float sensor system for automatic water/air level control. Manual flow control valves are provided for balancing the recycle rate, for the rate control of the air addition, the saturated recycle rate to the DAF inlet reaction jet, and the pump by-pass flow volume.

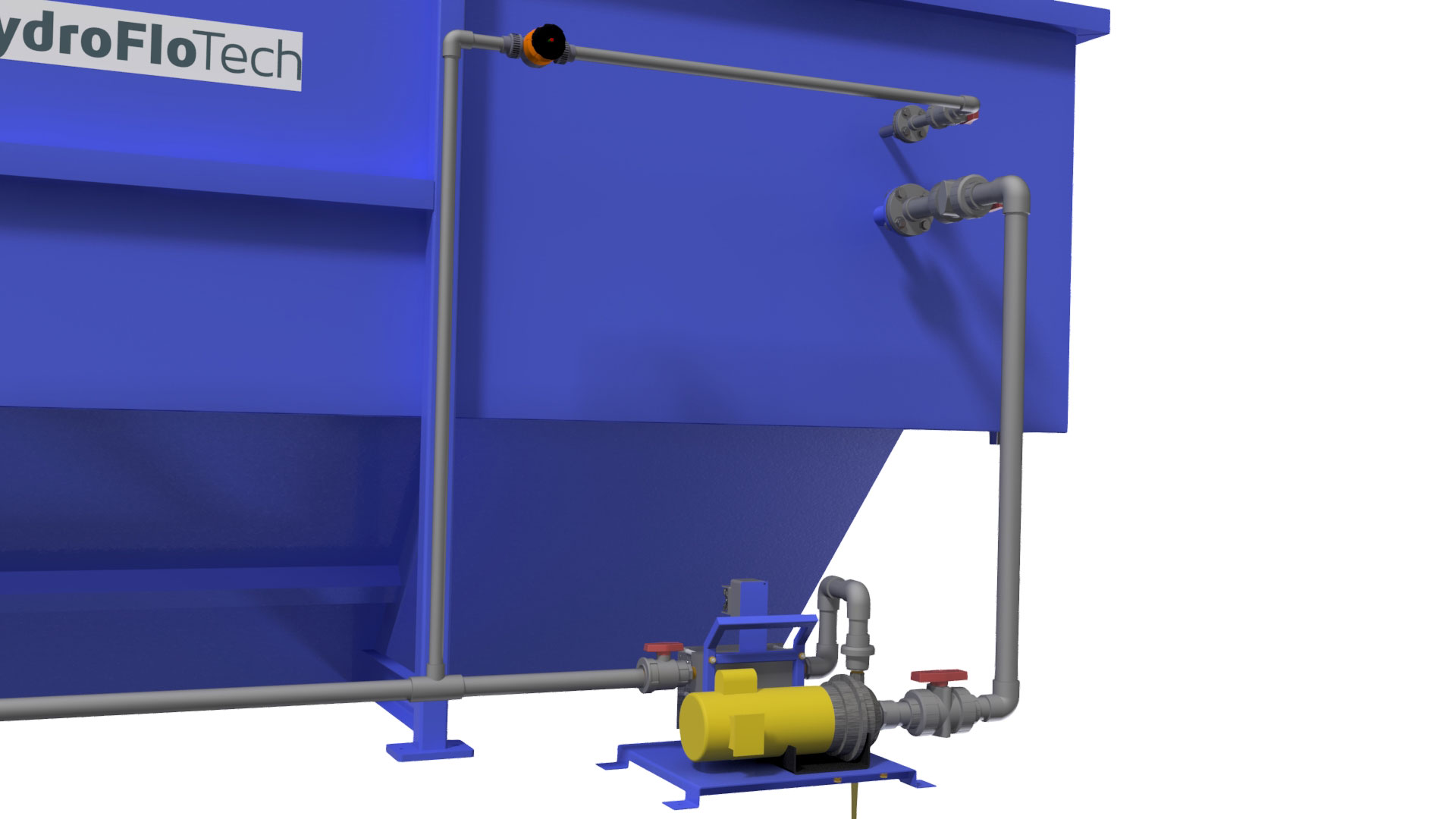

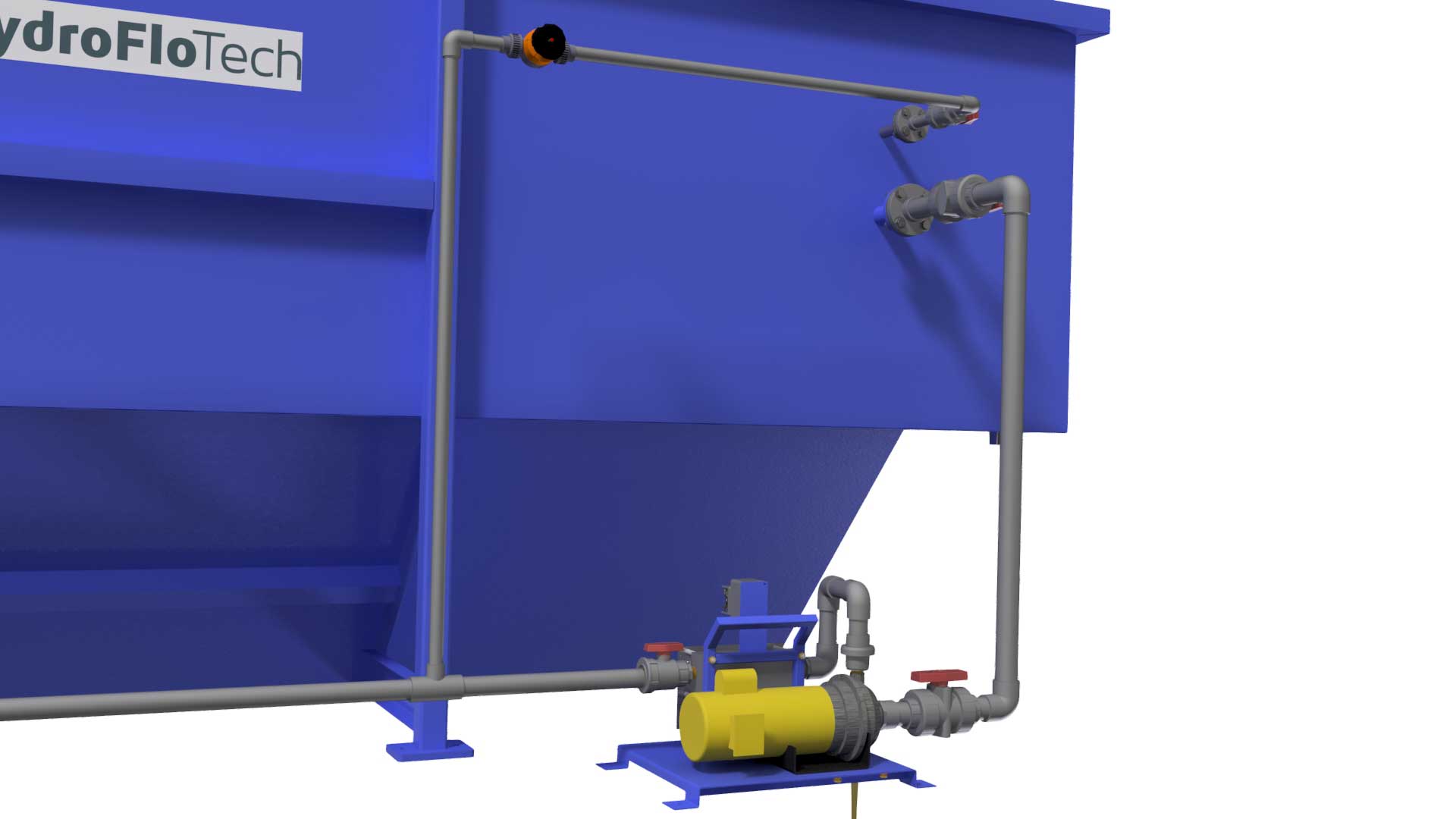

Option 2 Recycle / Air Dissolving System (CRAD):

The HydroFloTech DAF pump is specially designed to be used in dissolved air flotation (DAF) systems. · Clarified effluent from a DAF unit is pumped by the DAF pump under high pressure. Air is introduced into the pump suction by an eductor loop. The air is sheared into small bubbles by the pump and then dissolved into the water under high pressure. · When the pressure is released (at the DAF influent), the dissolved air comes out of solution in the form of tiny (~10 – 50 micron) bubbles. These tiny bubbles attach to oil, grease, and solid particles and float them to the surface of the DAF unit. The floated material is then removed from the surface by a skimming device.

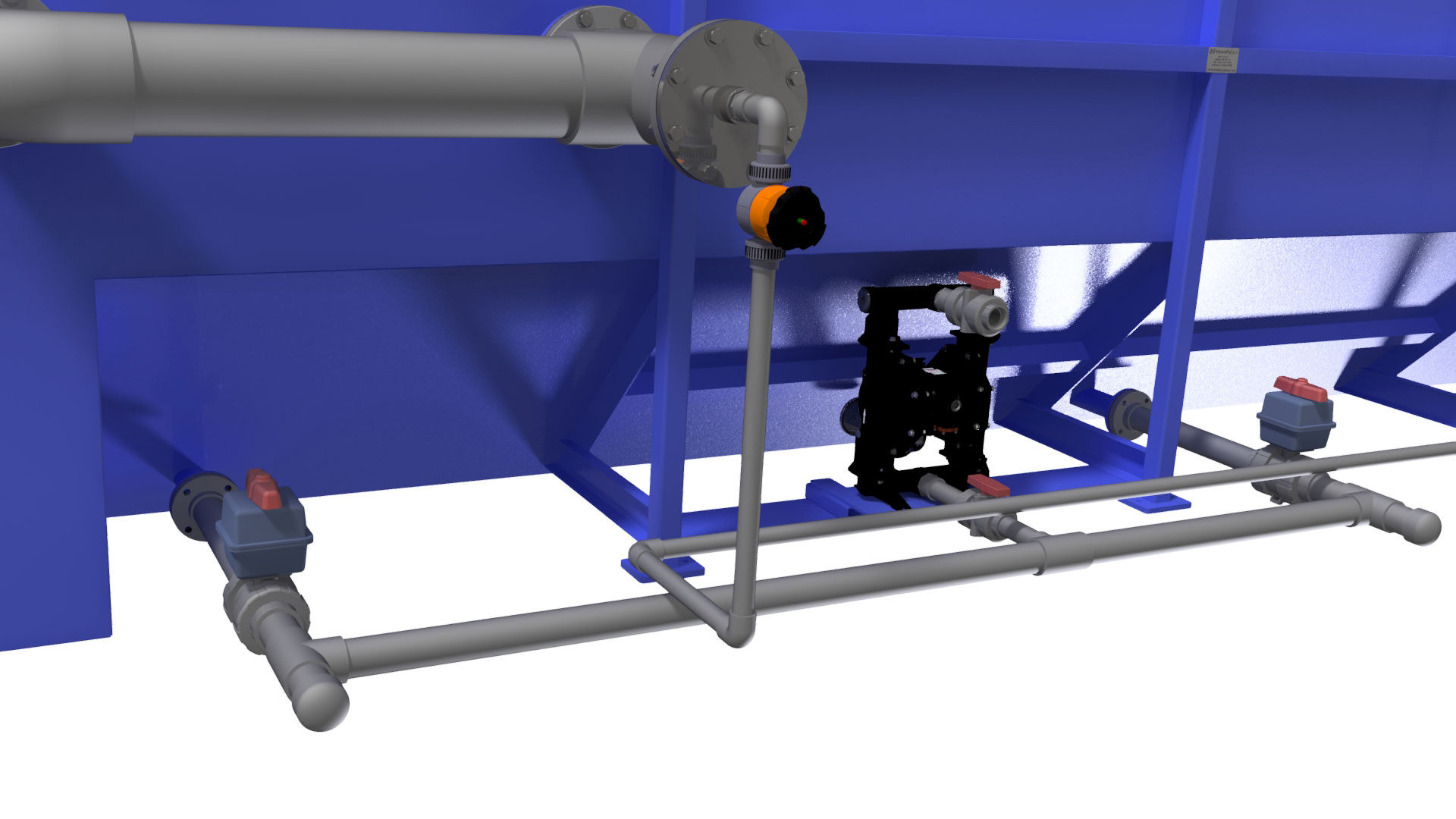

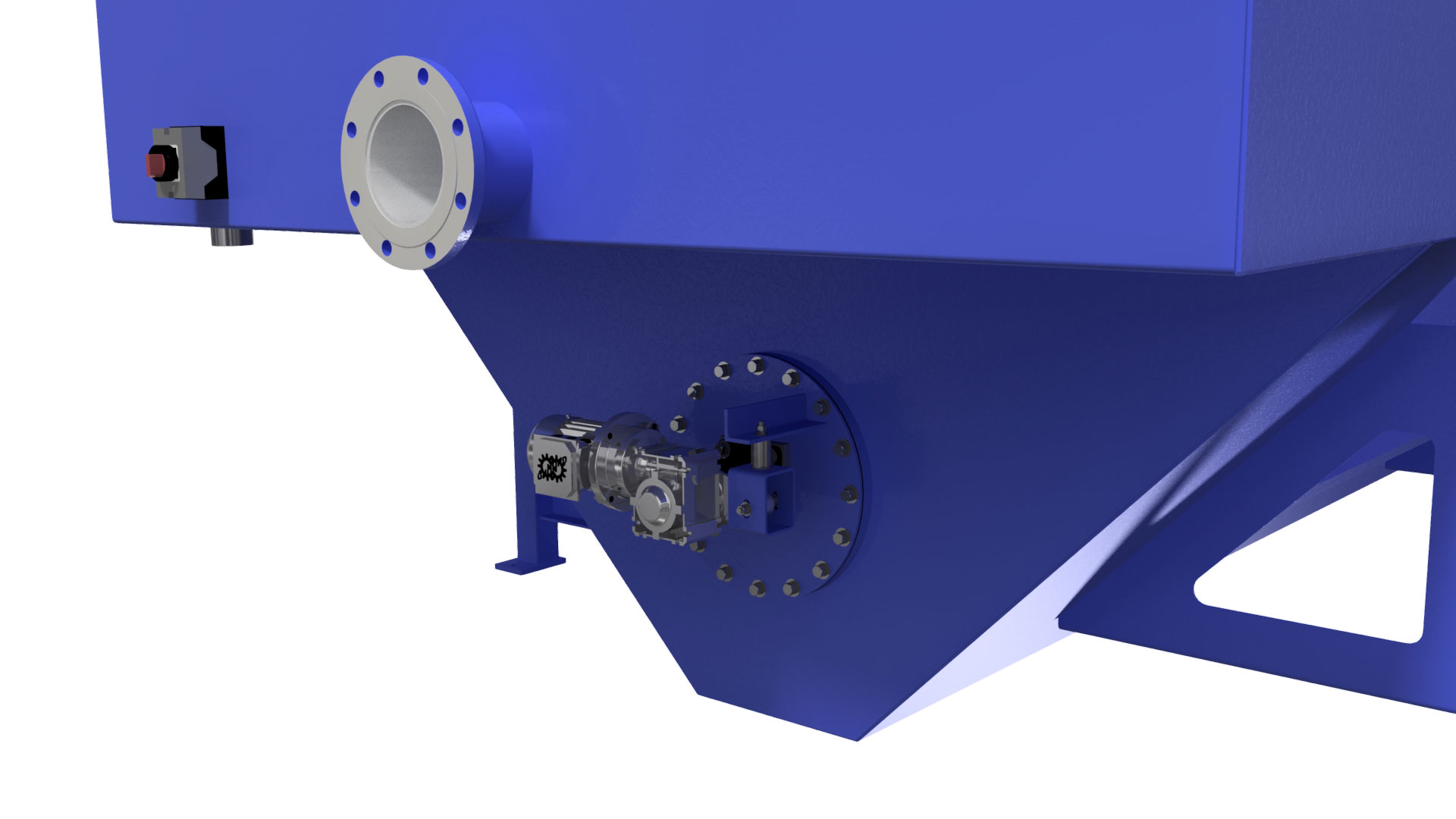

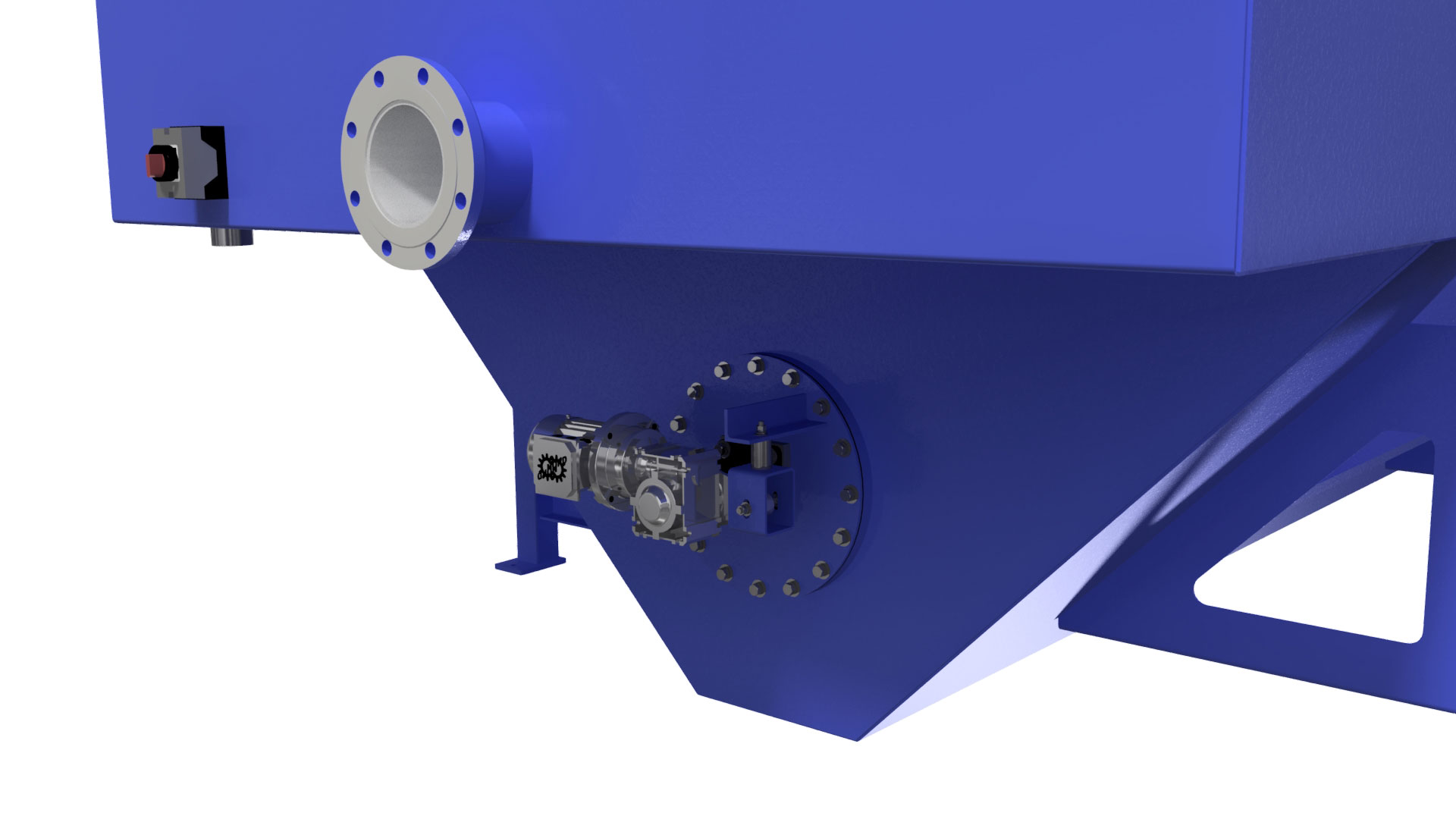

Integrated Mechanical Sludge Thickener (Optional)

The bottom sludge thickening auger is designed to turn/fold the sludge over (at a relatively slow rate) and conveying the sludge to a central discharge point (as opposed to stirring/turning the material in a single direction) results in a more consistent, less stratified sludge blanket. As the sludge compresses/thickens toward the center of the thickener and along the thickener’s compressing edge, water passes up into the clarifier at the thickeners ends and at its rising edge homogenize and dewater sludge and grit as it moves it to a central convergence point, where it freely flows out the sludge outlet nozzle. Our unique design allows us to use less HP drive mechanism because of the smaller overall diameter. The drive mechanism is attached directly to the thickener with a removable safety cover. The auger is accessible by submerged bolt-on manway with Buna-N gasket material.

The sludge collection area can be designed where a sludge thickening auger may be added at a later point in time.

Control Package:

All HydroFloTech dissolved air flotation systems are fully automated. Control packages (depending on your specific requirements) are available in either basic relay logic control, or a fully state of the art PLC with touch screen HMI and our sophisticated treatment algorithms. The relay logic controls package allow basic reconfiguration of the original system settings, while the PLC based package allows maximum flexibility to change the process parameters, as well as tight control that minimizes chemical usage. All enclosures are NEMA 4x.

Effluent Monitoring (optional): As and when mandated by the local controlling authority, the effluent quality must be continuously monitored. A two-pen recorder is to be used to monitor effluent flow rate and pH. The recorder is to be equipped with a flow totalizer. Any effluent pH deviations will trigger an alarm and system discharge will be halted.

| HYDROFLOATTM Dissolved Air Flotation (DAF) System – STANDARD PRODUCT DATA SHEET | ||||||||||

| MODEL # | CHAMBER CAPACITY | FITTING SIZE | ELEVATION | DIMENSIONS(in inches) | WEIGHT | |||||

| CU FT | Separation | Sludge | Influent (D) / Effluent (E) | Recycle Suction (F) | Influent (D-1) | Effluent (E-1) | LENGTH (L) | WIDTH (W) | HEIGHT (H) | Operating (lbs.) |

| DAF-HF-025 | 610 | 235 | 3 | 2 | 42 | 34 | 158 | 76 | 76 | 11,784 |

| DAF-HF-040 | 925 | 455 | 3 | 2 | 46 | 40 | 179 | 88 | 82 | 17,678 |

| DAF-HF-060 | 1,300 | 640 | 3 | 2 | 46 | 40 | 227 | 88 | 82 | 23,971 |

| DAF-HF-090 | 2,275 | 1,125 | 4 | 2 | 52 | 48 | 263 | 100 | 94 | 39,264 |

| DAF-HF-125 | 3,080 | 1,525 | 4 | 2 | 52 | 48 | 335 | 100 | 94 | 49,130 |

| DAF-HF-160 | 3,925 | 2,110 | 6 | 3 | 57 | 49 | 383 | 99 | 97 | 66,896 |

| DAF-HF-185 | 5,205 | 2,400 | 6 | 3 | 63 | 49 | 428 | 99 | 103 | 82,310 |

| DAF-HF-200 | 5,630 | 2,595 | 6 | 3 | 63 | 49 | 458 | 99 | 104 | 89,729 |

| DAF-HF-260 | 8,380 | 4,170 | 6 | 3 | 78 | 58 | 481 | 117 | 119 | 131,352 |

| DAF-HF-335 | 10,540 | 5,245 | 8 | 4 | 78 | 60 | 589 | 117 | 119 | 162,209 |

| DAF-HF-400 | 15,560 | 5,810 | 8 | 4 | 78 | 60 | 685 | 117 | 131 | 215,821 |

| DAF-HF-450 | 17,510 | 7,850 | 8 | 4 | 84 | 66 | 685 | 129 | 137 | 252,430 |

| DAF-HF-550 | 25,590 | 10,630 | 10 | 6 | 108 | 72 | 745 | 141 | 155 | 353,575 |

| DAF-HF-610 | 28,280 | 11,750 | 10 | 6 | 108 | 72 | 817 | 141 | 155 | 388,410 |

| Equipment Designing Data & Sizing Sheet Calculations | Drawings | Specifications | Installation, Operation & Maintenance Manual |

|---|---|---|---|

| DAF Design Parameters | DAF General Arrangement Drawing | “Common” Engineering Specification | DAF IO&M Manual |

| DAF Sizing Spreadsheet | General IO&M Considerations Applicable to all HydroFlo Manufactured Equipment |