Emulsion Breakdown Systems

Standard Features

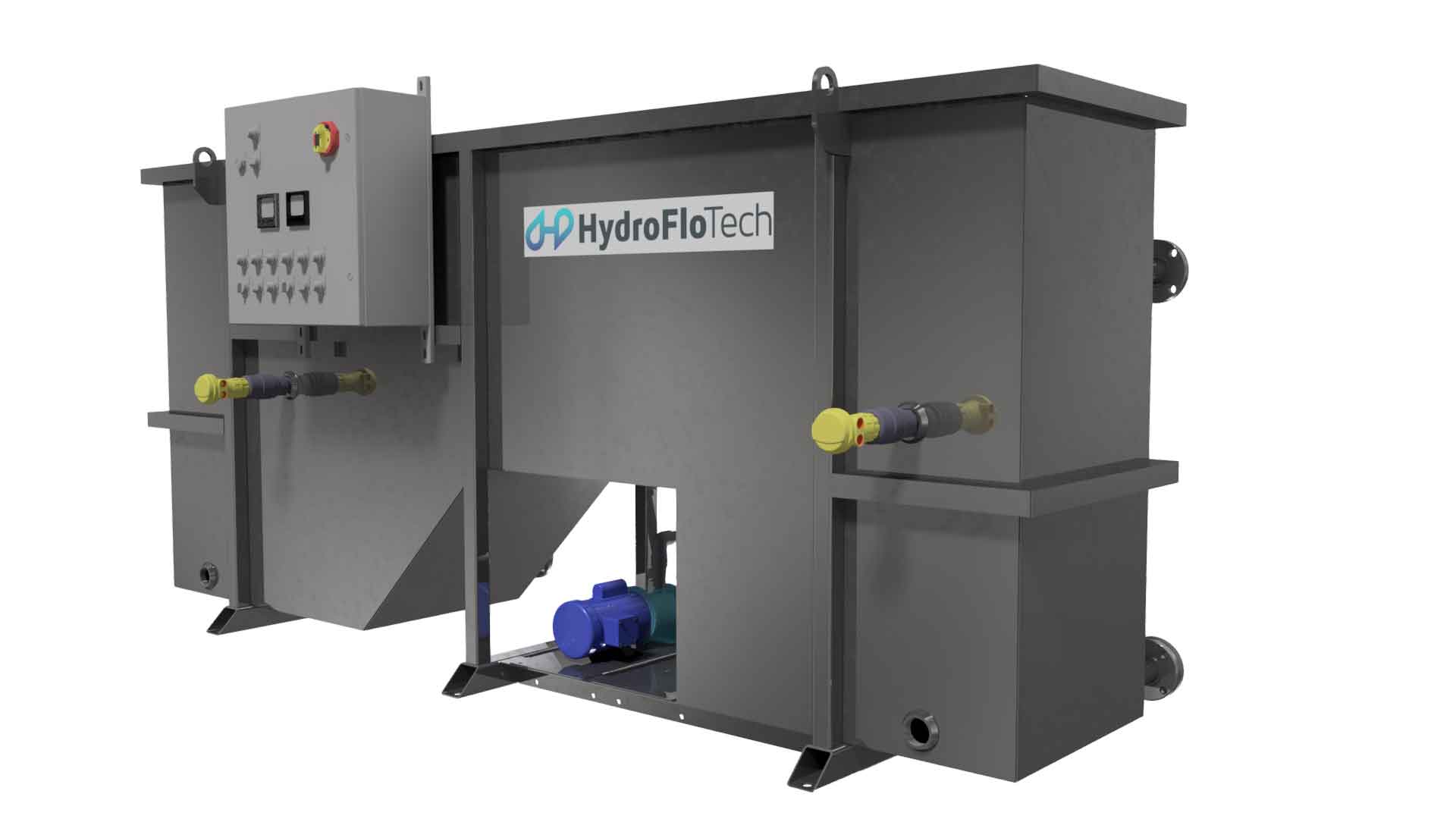

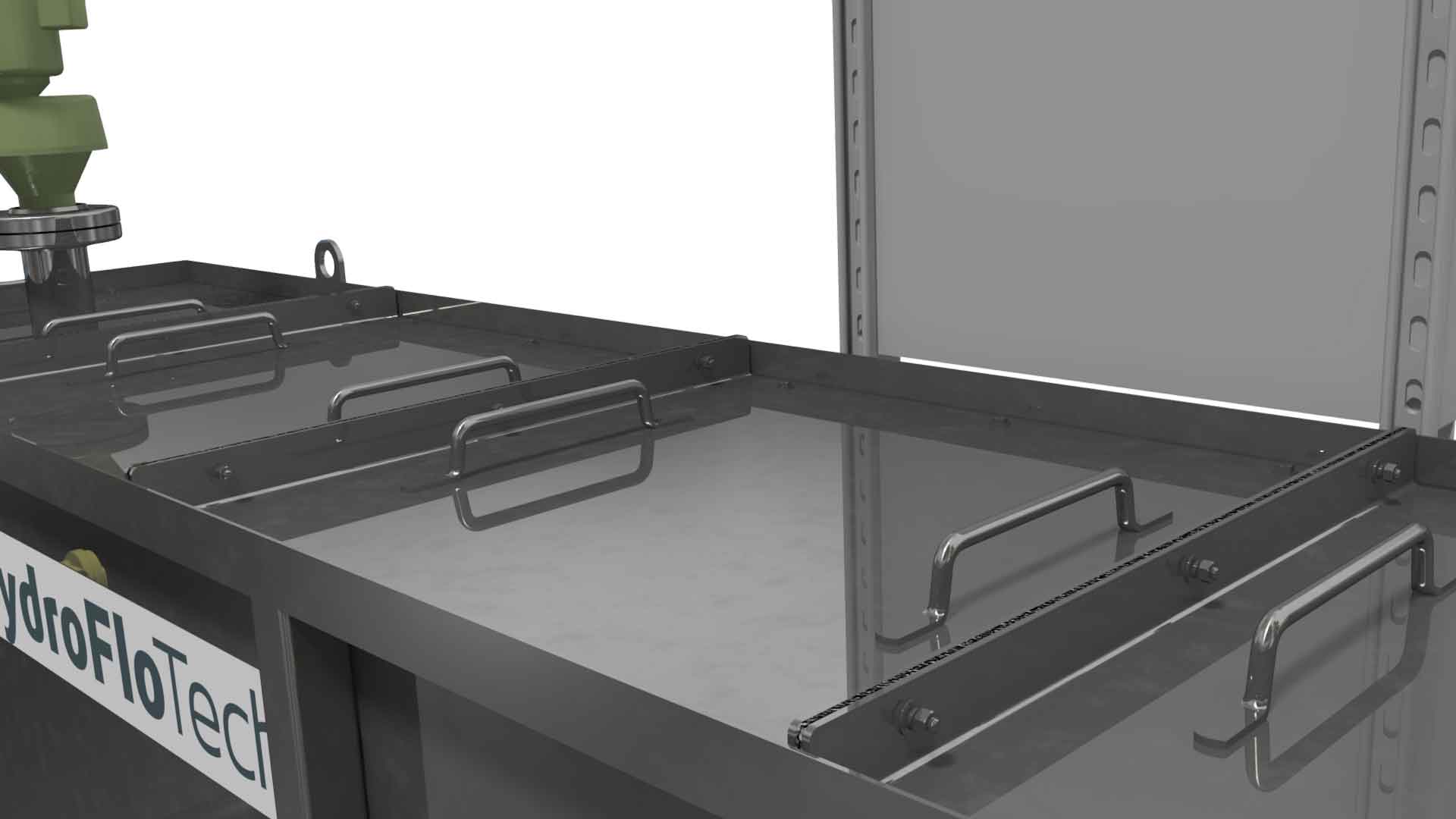

- Epoxy coated ASTM A-36 carbon steel three-chamber tank

- Automatic injection and mixing of chemicals in acid cracking (chamber 1) and pH readjustment (chamber 3)

- Free oil removal (Chamber 2) is a standard oil water separator with sludge removal and HydroFloTech proprietary DynaPacTM hi-density PVC coalescing media

- Fully automatic control panel.

Available Options

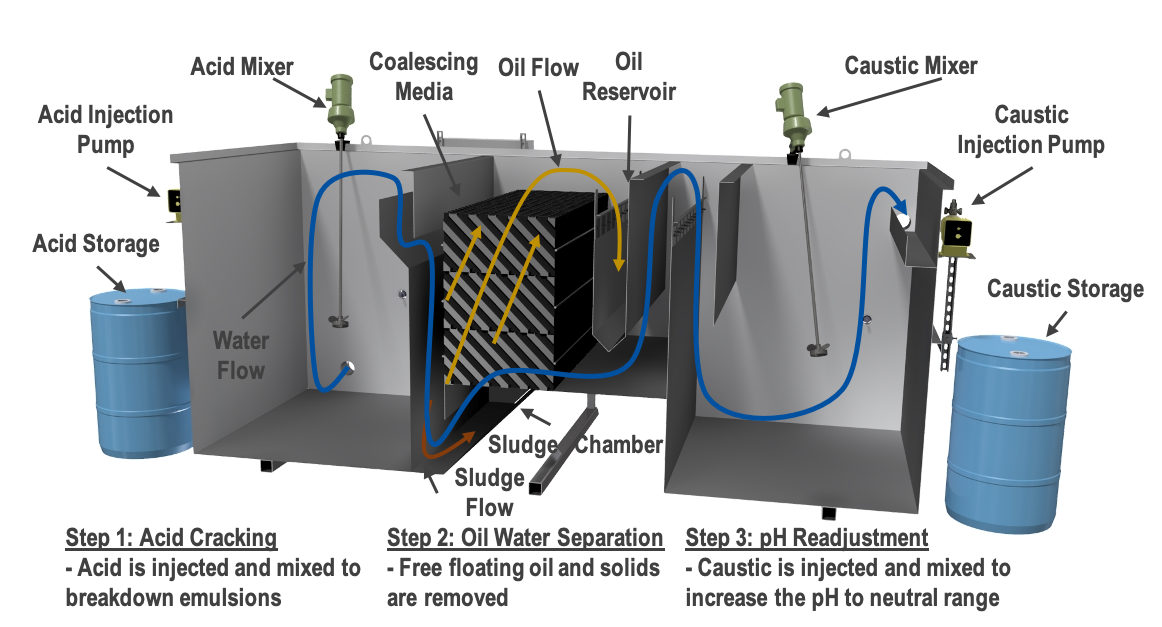

Most mechanical emulsified oils can be broken down by “acid cracking” or “acidulation” or injecting acid. Upon introducing acid in the water, the emulsified oils break free and become free floating. As a result, the free floating oils can be removed with a standard oil water separator. Once the free oils are removed, the pH is too low to for downstream processing / use. As a result, the pH is brought back to a neutral range.

One fully integrated, fully automated, gravity based emulsion breakdown system:

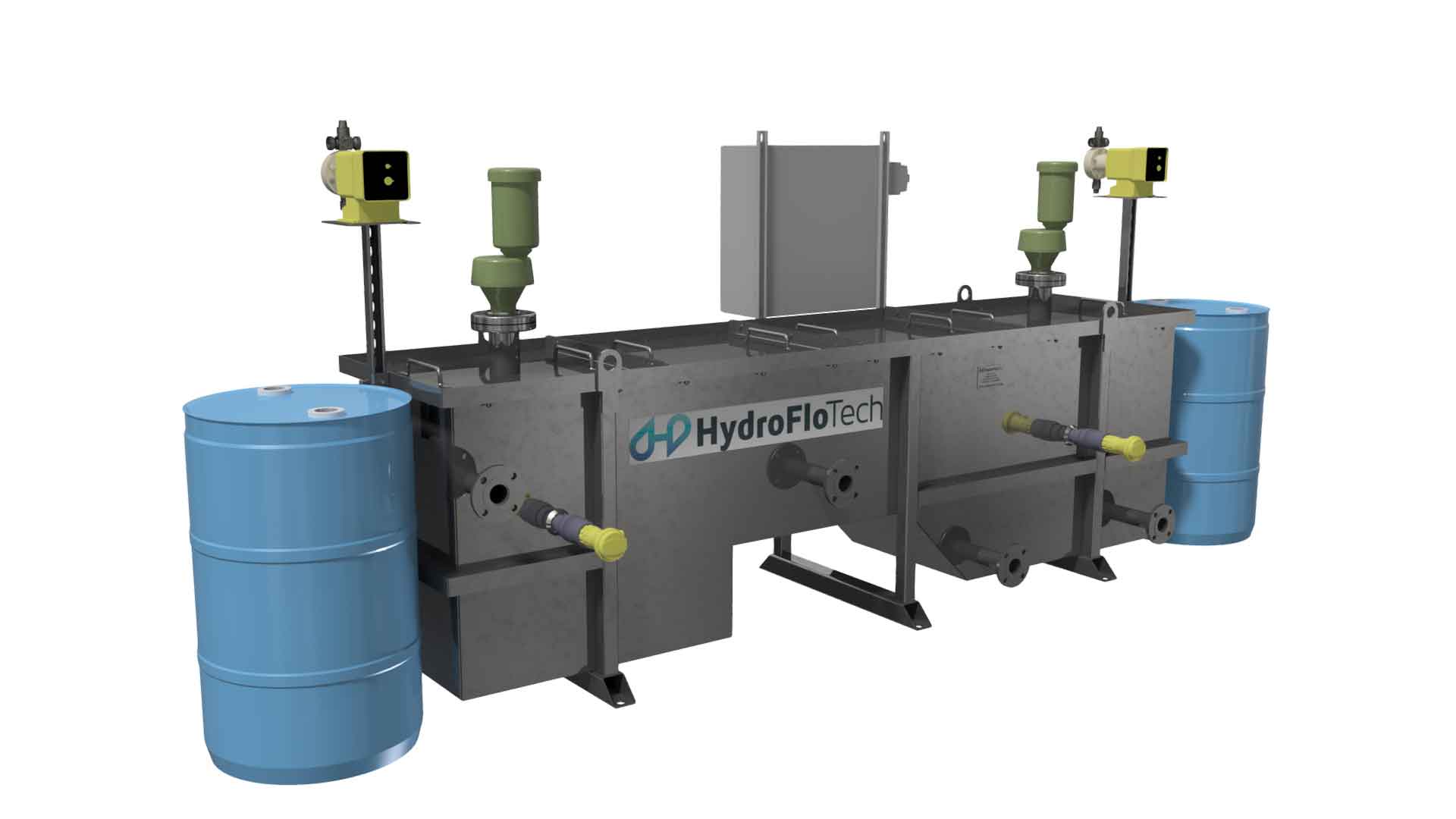

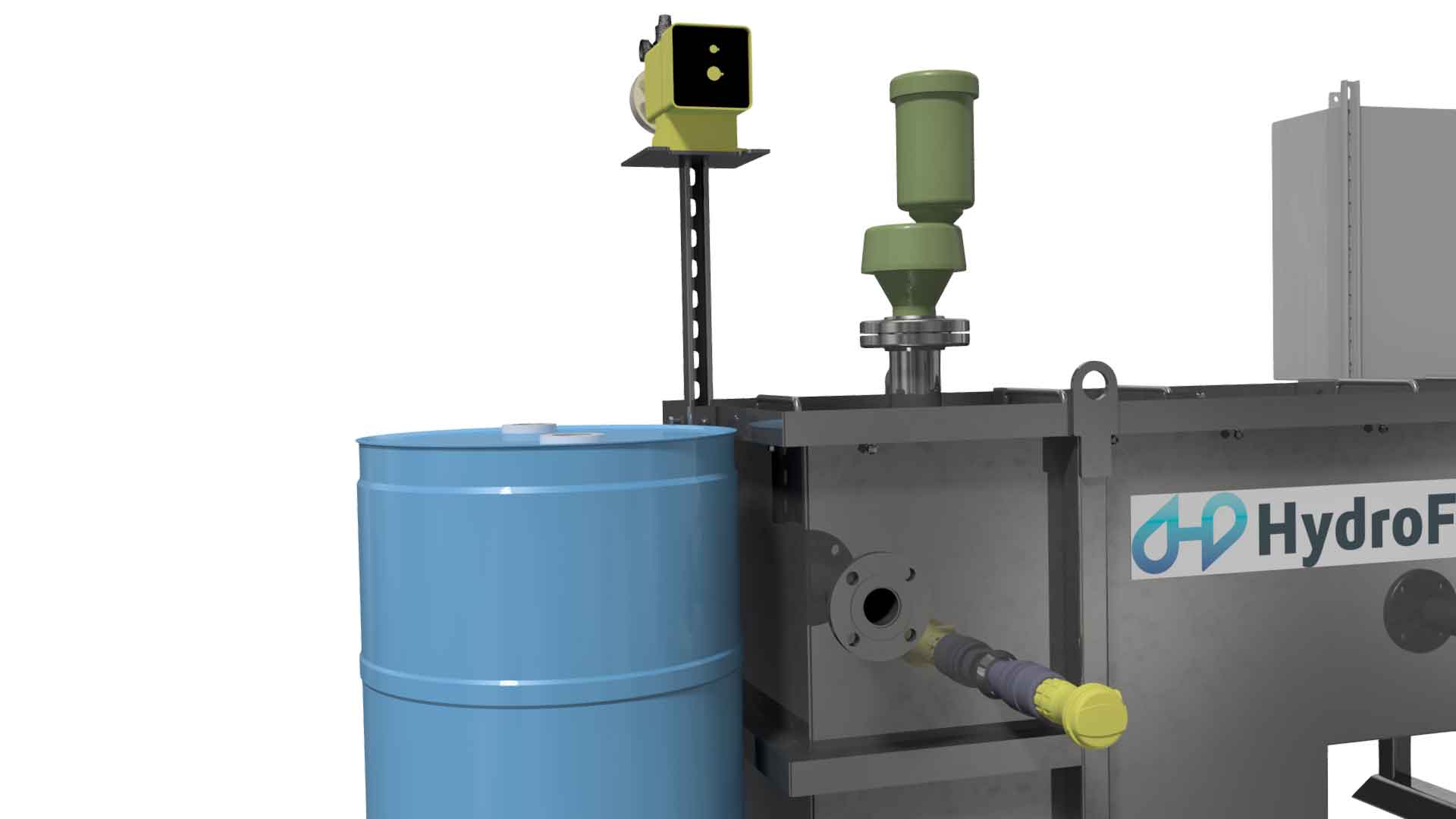

Step 1: “Acid Cracking” / “Acidulation” / Acid Injection

In this chamber, an acid injection pump pulses and doses the right amount of acid to drop the pH of the water to “crack” or “break” the emulsified compounds of oil into free floating oils. A pH probe and a mixer in the chamber ensure uniformity while the tank is sized appropriately for the required retention times.

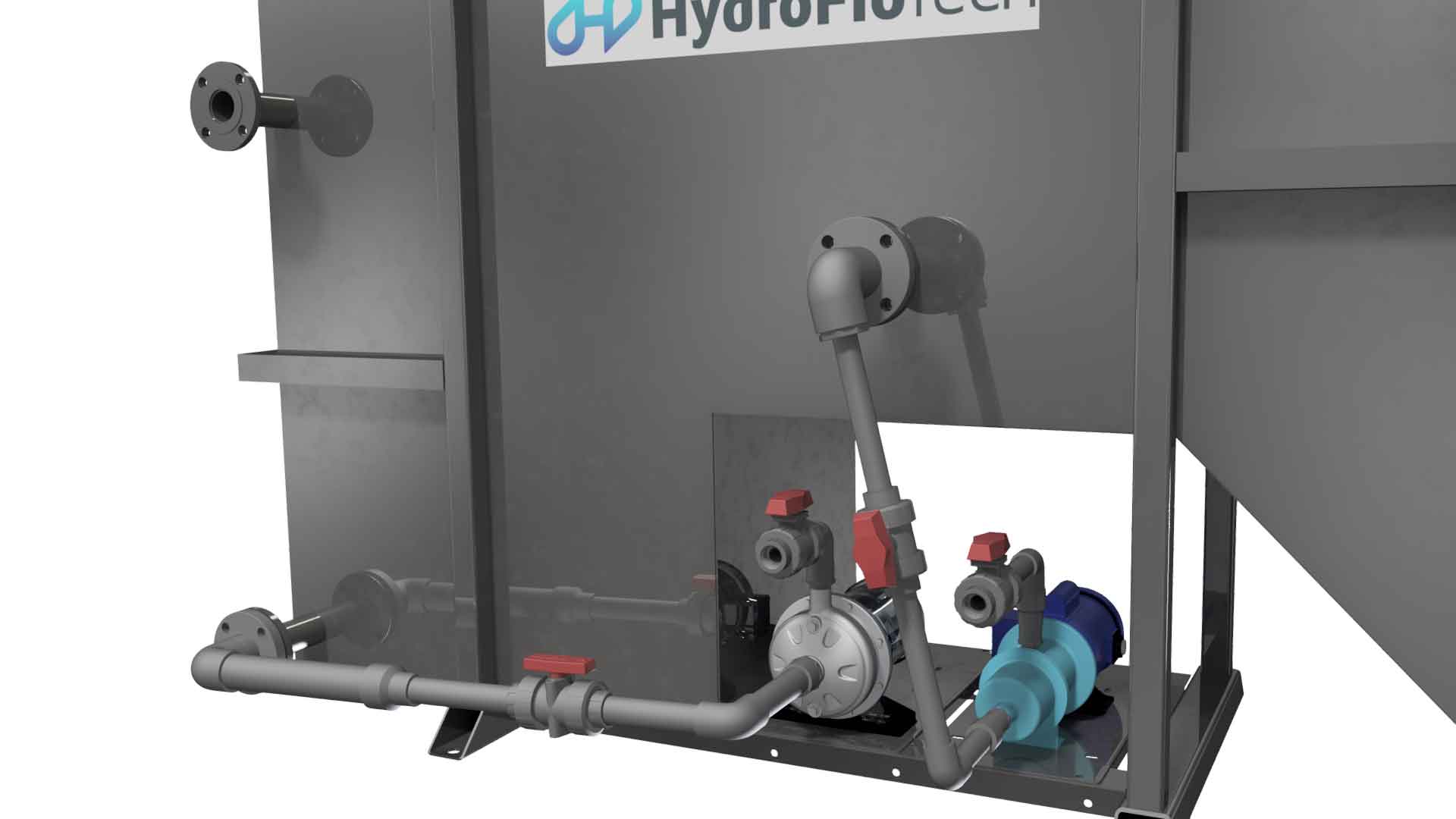

Step 2: Oil Water Separator

In this chamber, free oils (and in some cases solids that drop out as sludge) are separated from the water. The free oil, with its specific gravity being lower than water, will flow to the top. As water flows through the separation chamber, oil particles stay attached to the media while water flows through the unit. As oil accumulates, it will flow to the top and will be captured through a weir system. The sludge collection chamber shall be located directly beneath the coalescing media pack and provide ample storage capacity for the settled sludge. The sides of the chamber are sloped at 45 degrees to insure easy and complete removal of the settled sludge.

Step 3: pH Re-Adjustment

In this chamber, the pH is re-adjusted to a neutral (or any other desired) levels to allow for any further treatment or usage. Given that the lower pH that is required during “acid cracking”, the water is not suitable for most discharge / reuse purposes. As a result, pH is readjusted higher by automatically injecting caustic in this chamber. Similar to the automated system in Step 1 required for acid injection, a pH probe and a mixer are included in this chamber to ensure uniformity while the tank is sized appropriately for the required retention times.

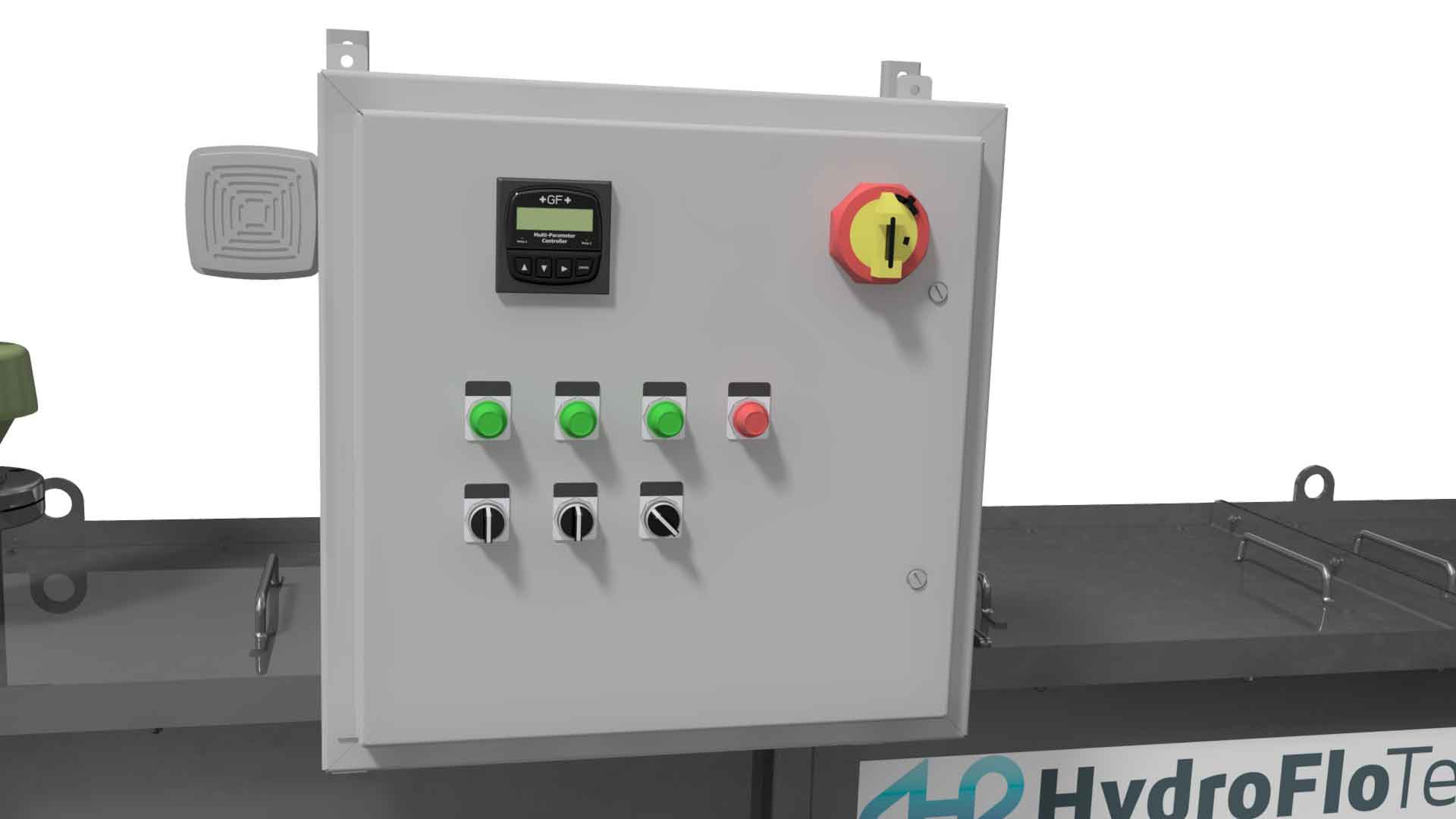

Control Package

HydroFloTech Emulsion Breakdown Systems or “EBX” Systems are fully automated. A NEMA 4x FRP local system control panel in standard. The local control panel includes an OSHA approved, fused power disconnect/lockout-tag-out switch, pilot lights to indicate motor operation, hand switches for mixer and chemical pump operation, all necessary motor starters.