Stinger

Standard Features

- 304 stainless steel tank

- Adjustable effluent V-notch troughs

- 304 stainless steel plate packs

- Standard units can be manufactured for flows from 5 gpm to 200 gpm and above

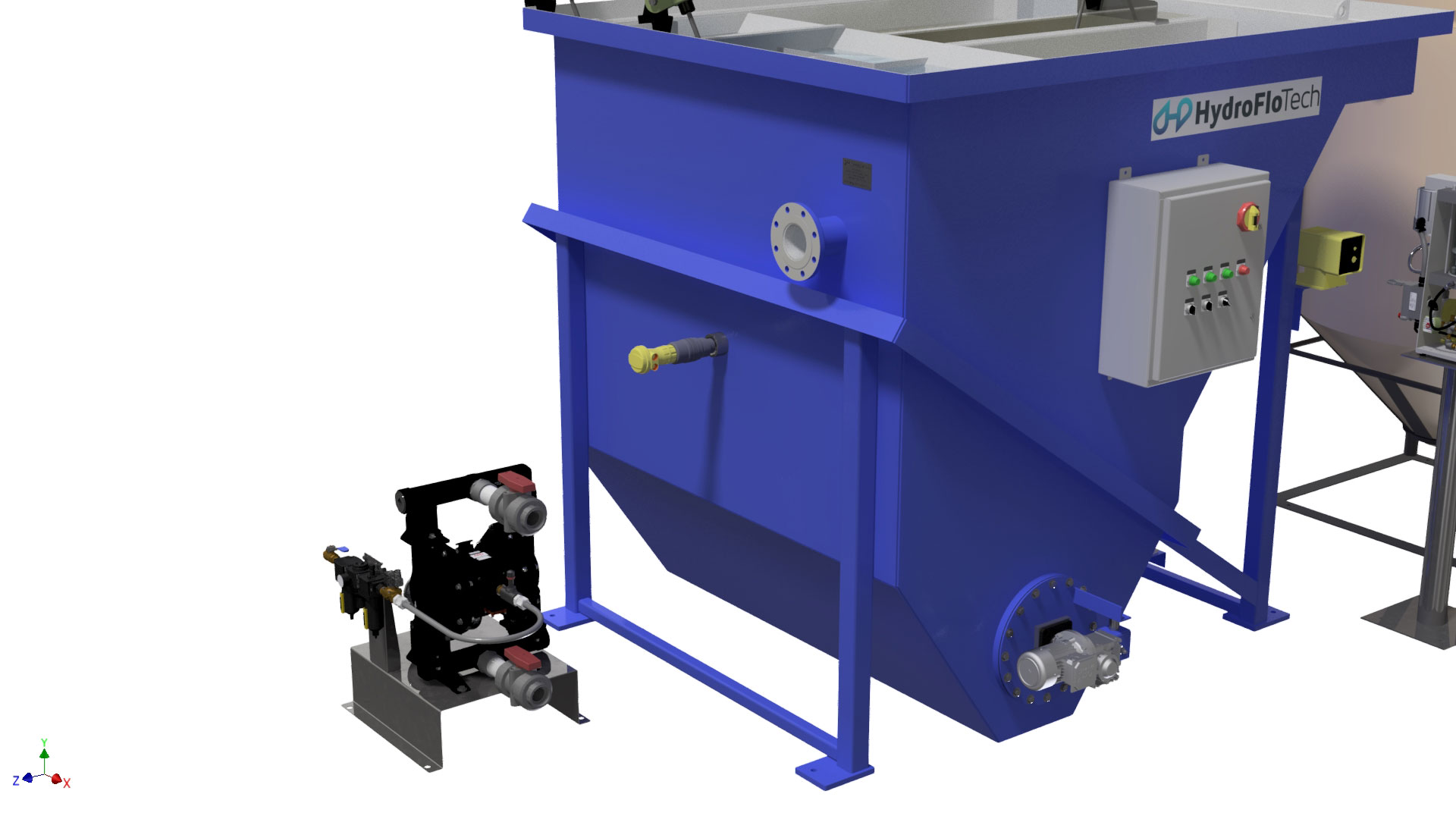

- Seamlessly integrates with other HydroFloTech wastewater products

Available Options

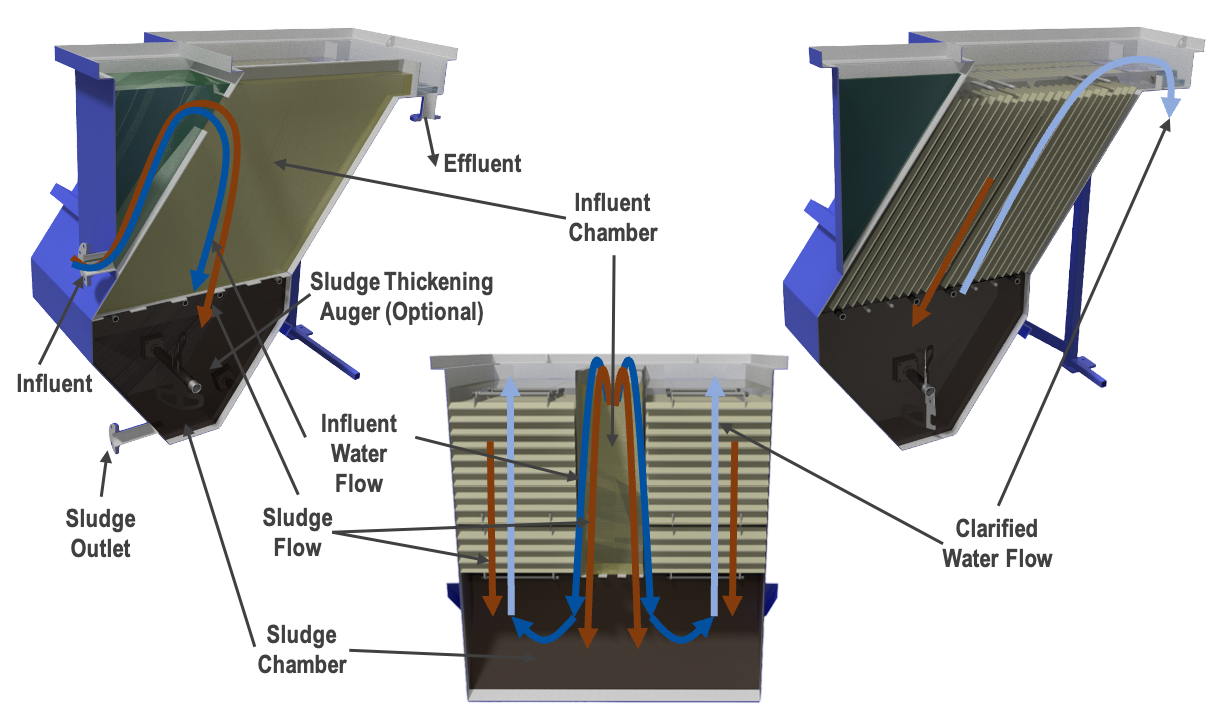

HydroFloTech Stinger Series Clarifiers have been refined over the years with various design improvements. Stinger Series Clarifiers use advanced fluid dynamic modeling to optimize laminar flow characteristics:

- Entering the plates: The design ensures quiescent flow and equal distribution. This confirms low turbulent flow through the separation process.

- Through the plates: In order to safeguard proper settling of solids, it is critical to maintain a laminar distribution of flow through the plates.

- Exiting the plates: As the water rises through the plates into the effluent v-notch and the effluent trough, an equal flow distribution is maintained.

In addition to optimizing flow through the plate pack, the Stinger Clarifier includes a large sludge collection hopper. The hopper combined with the optional integral mechanical sludge thickener, keeps sludge re-entrainment to a minimum. As an additional benefit, the pre-conditioned sludge has a high solids content.

The influent / effluent trough configurations, as well as the plate pack’s height to width ratios are optimized for seamless clarification. The attention to all these details ensures that the equipment performs exactly as designed.

Influent Distribution Chamber:

An influent distribution trough is provided to reduce influent velocities and uniformly distribute the flow to the plate pack. Laminar flow is established, and the hydraulic momentum of the incoming liquid is dissipated to prevent channeling. The HydroFloTech design uses oversized openings to prevent clogging of heavy suspended solids.

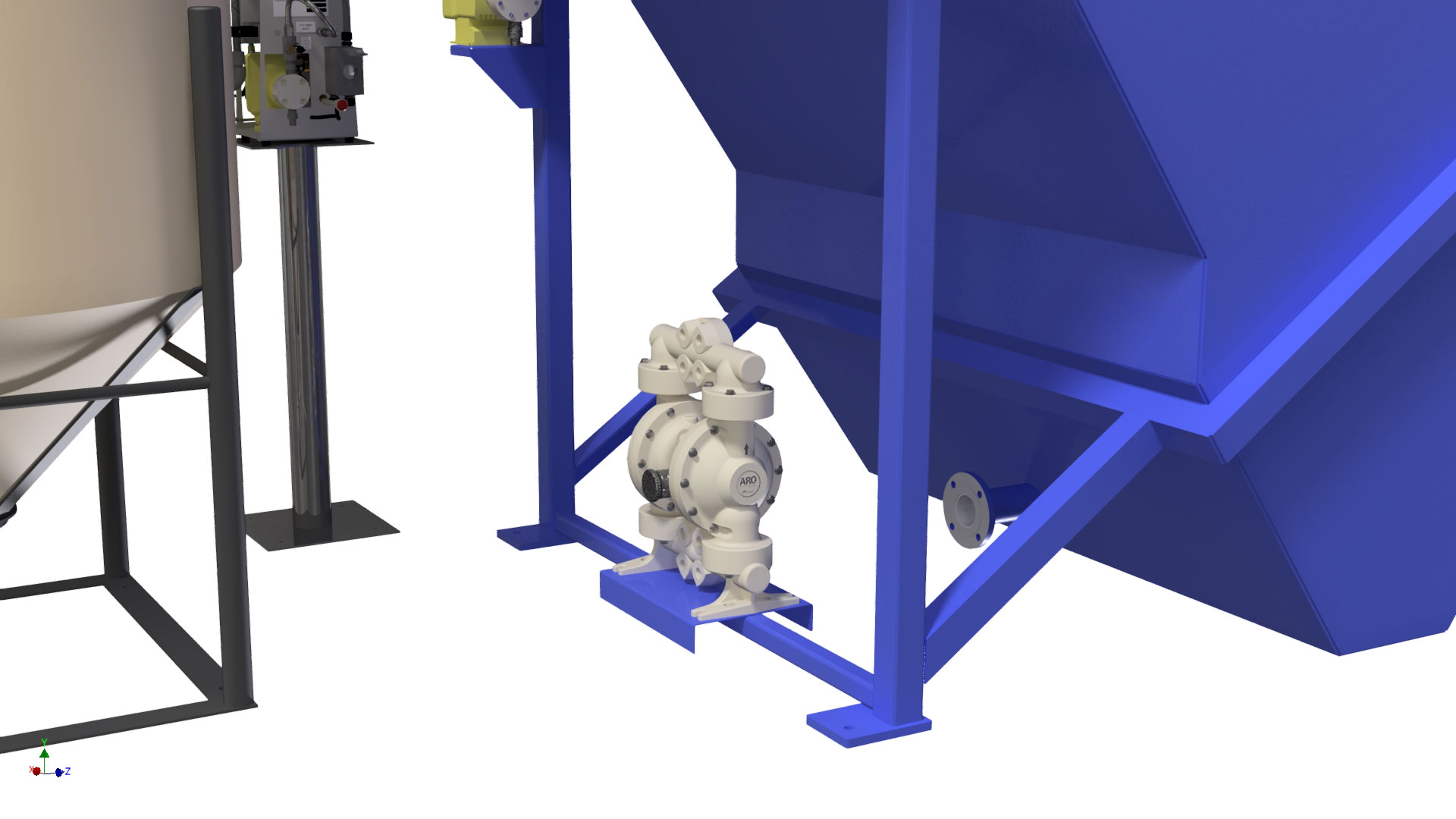

Main (up flow) Plate Pack:

Flow enters the main plate packs from the bottom, where the flow is evenly distributed throughout the pack. Flow travels up through the pack, toward the effluent overflow V-notch weirs, where the clarified water is carried toward the separator discharge.

Plate Pack:

HydroFloTech plate packs are fabricated out 304 stainless steel. This material of construction ensures longevity and ease of maintenance. HydroFloTech platepacks are also designed to become modular where they can be swapped out in the future for higher flowrates (e.g. 2” spaced plates can be swapped out for 1” plates to allow for increased flowrate situations).

Effluent Overflow Weirs:

The effluent overflow weirs are designed to control uniform flow throughout all plate compartments, and also over the entire width of the plates. The Stinger clarifier utilizes a V-notch type weir. This allows for uniform flow distribution, and also makes installation and leveling the system easier than other designs.

Sludge Collection Hopper:

HydroFloTech Stinger Series Clarifiers come standard with a horizontal hopper bottom. Many applications may also benefit from an optional integral sludge thickener. This design will break up compacted sludge and direct the sludge to the center discharge point. This design also allows for the maximum amount of sludge storage below the plates for a given height (three time as much as a cone bottom design).

Optional Sludge Thickening Auger

The bottom sludge thickening auger is designed to turn/fold the sludge over (at a relatively slow rate) and conveying the sludge to a central discharge point (as opposed to stirring/turning the material in a single direction) results in a more consistent, less stratified sludge blanket. As the sludge compresses/thickens toward the center of the thickener and along the thickener’s compressing edge, water passes up into the clarifier at the thickeners ends and at its rising edge homogenize and dewater sludge and grit as it moves it to a central convergence point, where it freely flows out the sludge outlet nozzle. Our unique design allows us to use less HP drive mechanism because of the smaller overall diameter. The drive mechanism is attached directly to the thickener with a removable safety cover. The auger is accessible by submerged bolt-on manway with Buna-N gasket material.

The sludge collection area can be designed where a sludge thickening auger may be added at a later point in time.

| Stinger™ Clarifier – Standard Model Specifications | |||||||

| MODEL # | 2″ PLATE SPACE | 1″ PLATE SPACE | UNIT DIMENSIONS (inches) | ||||

| CU FT | SQ FT | GPM* | SQ FT | GPM * | L | W | H |

| LS-010 | 34 | 12-Sep | 68 | 17 – 24 | 3′ – 4″ | 8” | 7’ 4” |

| LS-020 | 68 | 17 – 24 | 137 | 35 – 48 | 4′ – 4″ | 8” | 7’ 4” |

| LS-030 | 103 | 26 – 37 | 206 | 52 – 73 | 5′ – 1″ | 8” | 7’ 4” |

| LS-040 | 137 | 35 – 48 | 275 | 69 – 97 | 5′ – 10″ | 8” | 7’ 4” |

| LS-050 | 172 | 43 – 61 | 344 | 86 – 121 | 6′ – 10″ | 8” | 7’ 4” |

| LS-060 | 206 | 52 – 73 | 412 | 103 – 145 | 7′ – 7″ | 8” | 7’ 4” |

| LS-070 | 240 | 60 – 84 | 481 | 121 – 169 | 9′ – 4″ | 8” | 7’ 4” |

| LS-080 | 275 | 69 – 97 | 550 | 138 – 193 | 10′ – 7″ | 8” | 7’ 4” |

| LS-090 | 309 | 78 – 109 | 619 | 155 – 217 | 11′ – 4″ | 8” | 7’ 4” |

| LS-100 | 344 | 86 – 121 | 688 | 172 – 241 | 12′ – 1″ | 8” | 7’ 4” |

| Equipment Designing Data & Sizing Sheet Calculations | Drawings | Specifications | Installation, Operation & Maintenance Manual |

|---|---|---|---|

| Theory of Inclined Plate Clarifier Design | Stinger General Arrangement Drawing | “Common” Engineering Specification | LS Series IO&M Manual |

| Test for Determination of Clarifier Hydraulic Loading Ratio | General IO&M Considerations Applicable to all HydroFlo Manufactured Equipment | ||

| Clarifier Settling Velocity Spreadsheet | |||

| Stinger Sizing Spreadsheet | |||

| Clarifier Design Parameters |