Design and Sizing of a Dissolved Air Flotation Separator

If you are unfamiliar with basic DAF separator design principles, a review of the “Dissolved Air Flotation Theory of Operation” might prove helpful.

This basic document covers Stokes’ law and other basic separation concepts.

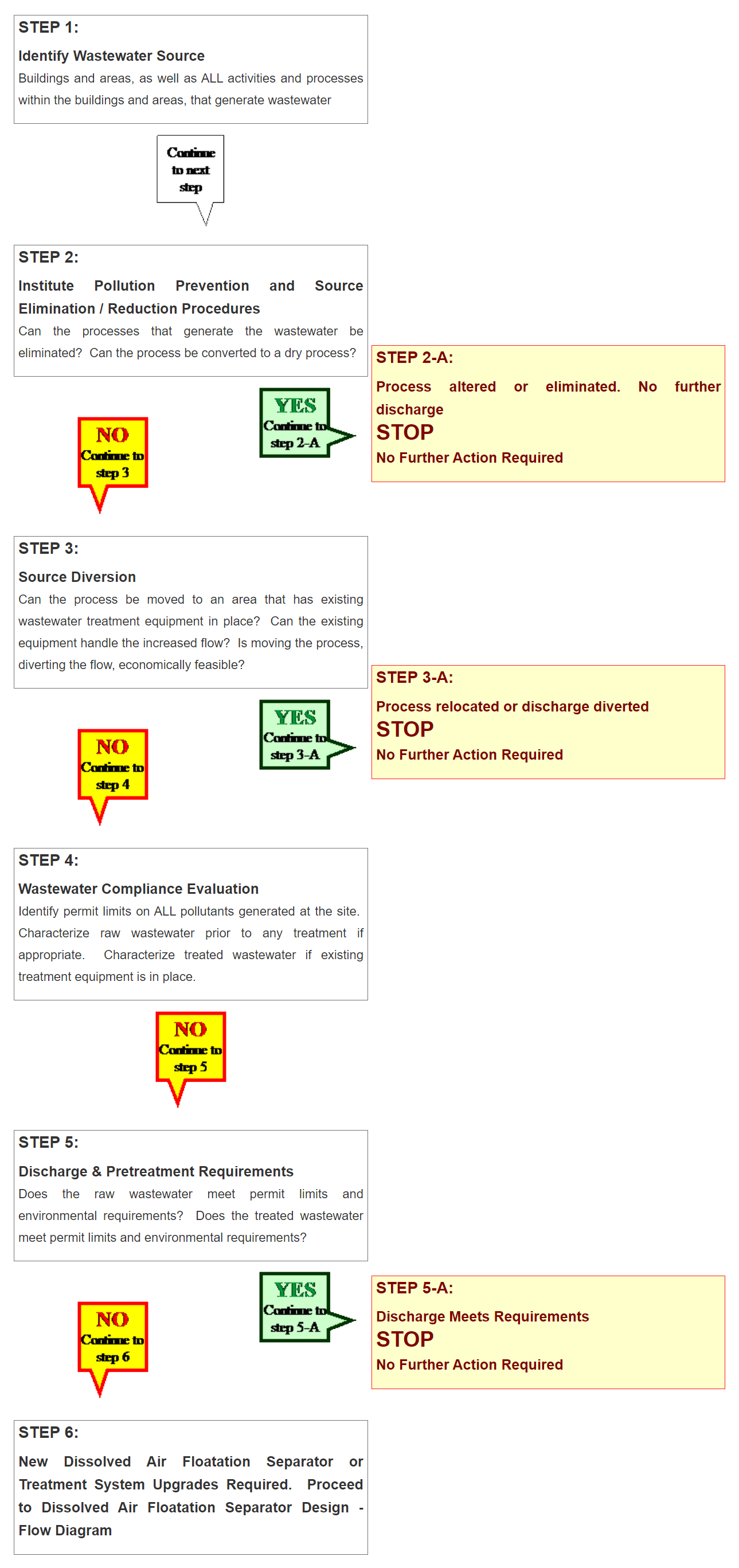

DAF separators are typically considered very simple devices. However, several factors that could potentially affect safety, efficiency, and proper management must be given careful consideration prior to the installation or modification of any DAF separator or separation system:

- Flow Rate

In general, DAF separators are sized by the flow rate verses the separation chamber’s effective surface area (or projected surface area in the case of a DAF with enhanced “coalescing” or parallel plate media). Therefore, the effectiveness of any DAF separator is affected by the flow rate. The slower the flow, the better the results. - Design Capacity

A DAF separator has upper limits to the amounts of FOG (fats, oils and grease) and TSS (total suspended solids) that can effectively accumulate while it is in operation. If too much product accumulates in the receiving and middle chambers, it may flow into the wastewater outlet chamber and end up being discharged to the environment. Proper DAF design will allow for the removal and storage of accumulated products from the separator to ensure that the accumulated products do not effect the operation of the separator. - Emulsifying Agents

Detergents and soaps designed to remove solids and oily grime from equipment, vehicles, or other components can adversely affect the operation of a DAF separator. These types of surfactants, or “emulsifying” agents, are specifically formulated to increase the dispersal of solids, oils, greases, etc. into water, which is why they are such good cleaners. When these soapy wastewaters enter a DAF, it takes significantly longer for the products to separate, if they can, from the water. Excessive use of detergents can render an oil water separator inefficient by completely emulsifying oils into the wastewater stream and allowing them to pass through the system. Low-emulsifying soaps are available that allow oil separation to occur more quickly after the soapy water enters the oil water separator. - Maintenance Practices

The ability of DAF separators to function properly depends upon the timely performance of required service and maintenance. DAF separators must be monitored and maintained by competent personnel who understand how the systems operate. DAF separators should be given the same close attention given to any other important piece of equipment. The operators, users, and maintainers of the DAF separator must clarify who will be responsible for monitoring, inspecting, maintaining, and servicing the system. Frequent inspections should be made of the system and all associated piping, valves, etc. to prevent operational and mechanical failures or inefficiencies. Sludge and oil need to be periodically removed from the DAF separator to keep it operating properly. Additionally, leaks from DAF separators can result in environmental pollution, which can trigger costly investigative studies and cleanups. Rigorous implementation of a DAF inspection and maintenance plan can prevent discharges from the DAF separator that may contaminate the environment. - Suitability of Dissolved Air Flotation Separation System to Process

A DAF separator designed and installed to meet a past process requirement may no longer be suitable when process requirements change, and/or the original maintenance plan is no longer followed. A DAF separator that is put to a use for which it was not originally designed may be damaged or may not function properly, and could become an environmental liability. For example, a DAF separator designed to receive the wastewater discharge from a small engine wash rack will not be able to properly treat larger wastewater volumes from washing the exterior of locomotives. Process changes can also result in changes to the physical/chemical makeup of the wastewater being treated by a DAF separator. Finally, process changes may also necessitate the modification of storm water and wastewater drainage systems. Such systems should remain separate from each other because excessive drainage of storm water to a DAF separator could significantly impair its operation and efficiency. - Contaminants Contained in the Wastewater Stream

Metallic particles in the wastewater will settle into the sludge at the bottom of the DAF separator. Solvents or fuel compounds may also be entrained in the DAF separators’ sludge. This sludge could require management under the Resource Conservation and Recovery Act (RCRA) as a hazardous waste if it exhibits certain toxicity characteristics. Therefore, it is important to prohibit the discharge of certain types of potential contaminants into a DAF separator, and to regularly analyze sludge samples to determine toxicity prior to disposal. To reduce the accumulation of sludge, floors should be dry-swept before washing. General improvements in spill/drip control and containment of hazardous materials and oils will also reduce the amount of contamination in DAF separator discharges.

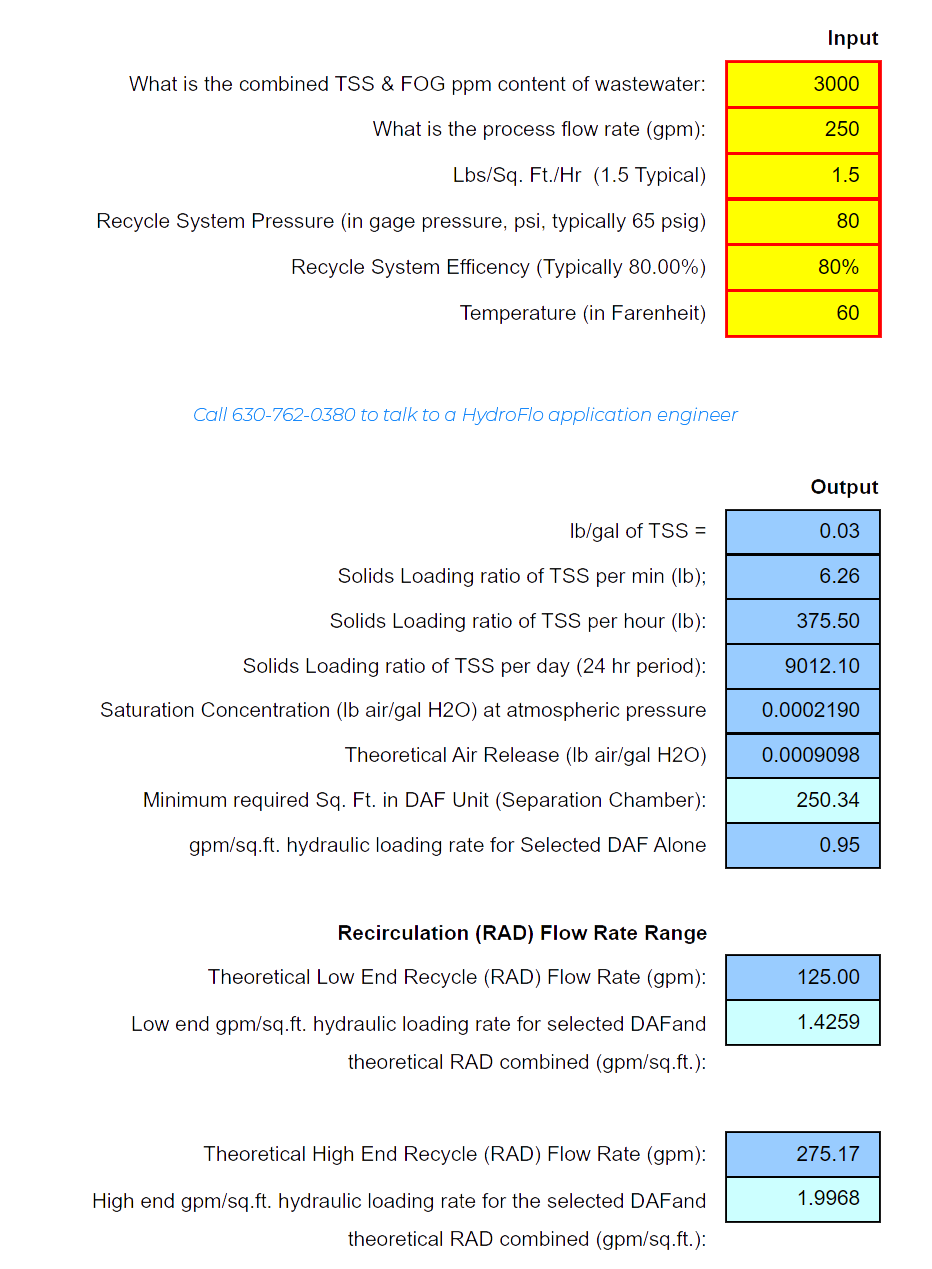

There are many factors that impact the overall design of a dissolved air flotation system, but the most important by far is the combined TSS & FOG (in parts per million) content of the wastewater. For example, look at the following spreadsheets.

This spreadsheet will calculate a DAF unit based on ppm of TSS & FOG combined, Flow rate and acceptable A/S ratio:

The final step is to insert the data into the “dissolved air flotation separator sizing spreadsheet“.

Comparing DAF proposals is basically straight forward as long as the engineering is correct. How many square feet of surface area is the defining criteria. Typically if everyone is bidding a 50 square foot DAF system, the units are all going to be comparable.

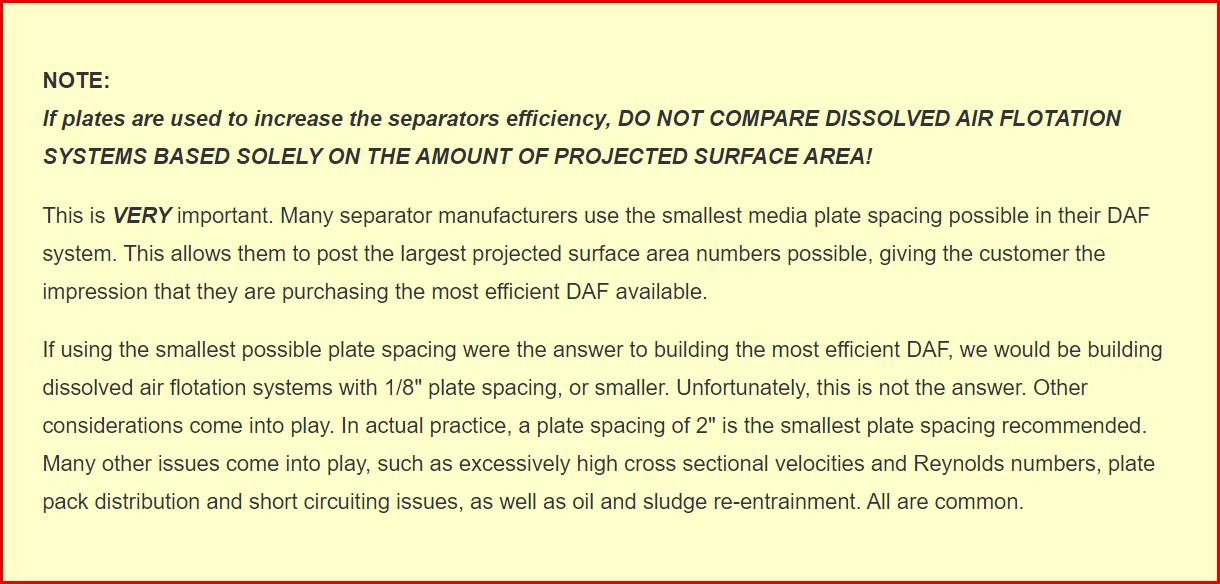

If they are bidding a DAF with parallel plates installed (to improve the units overall efficiency) then you must be carful to make sure that everyone is on the same page