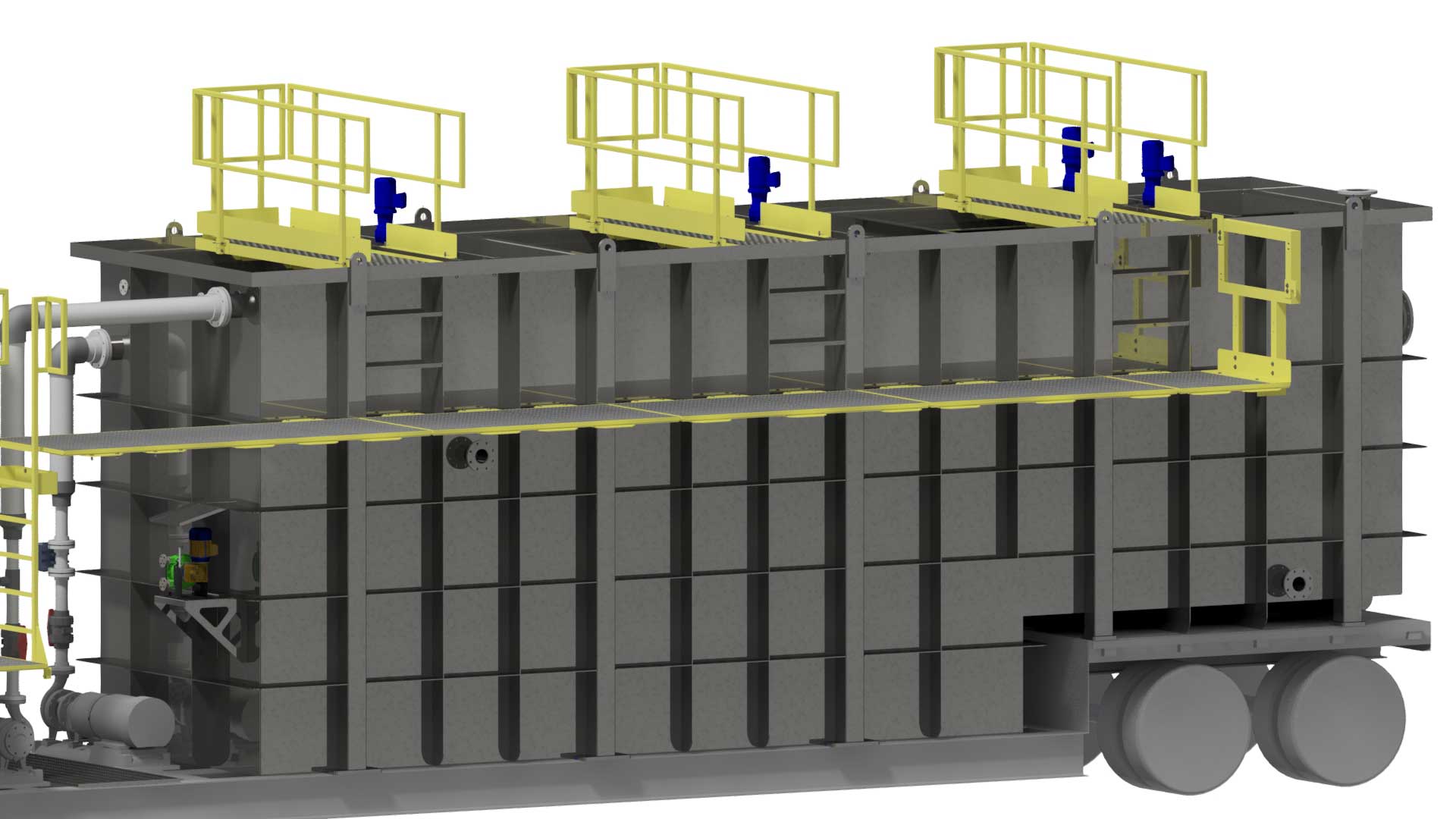

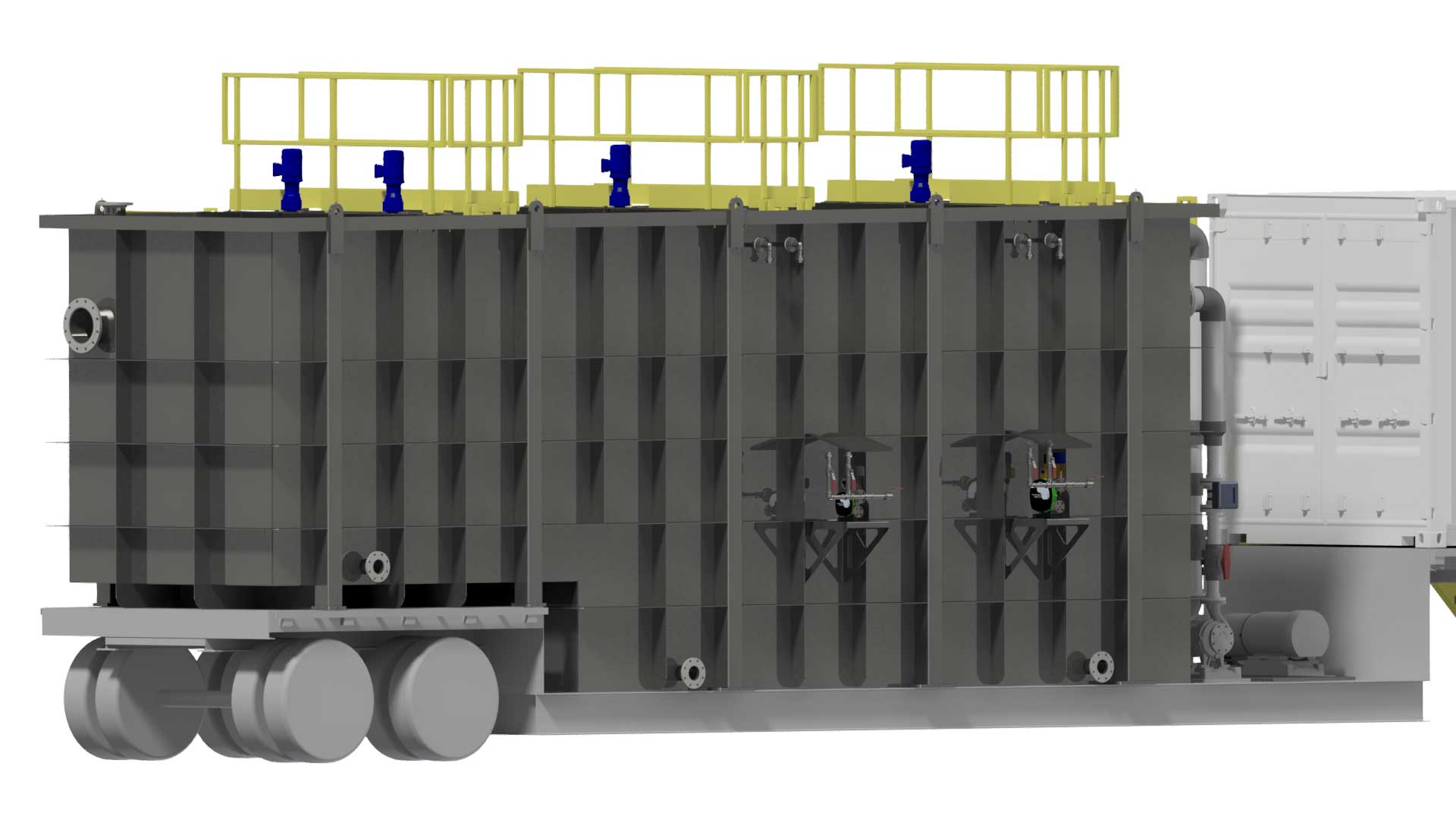

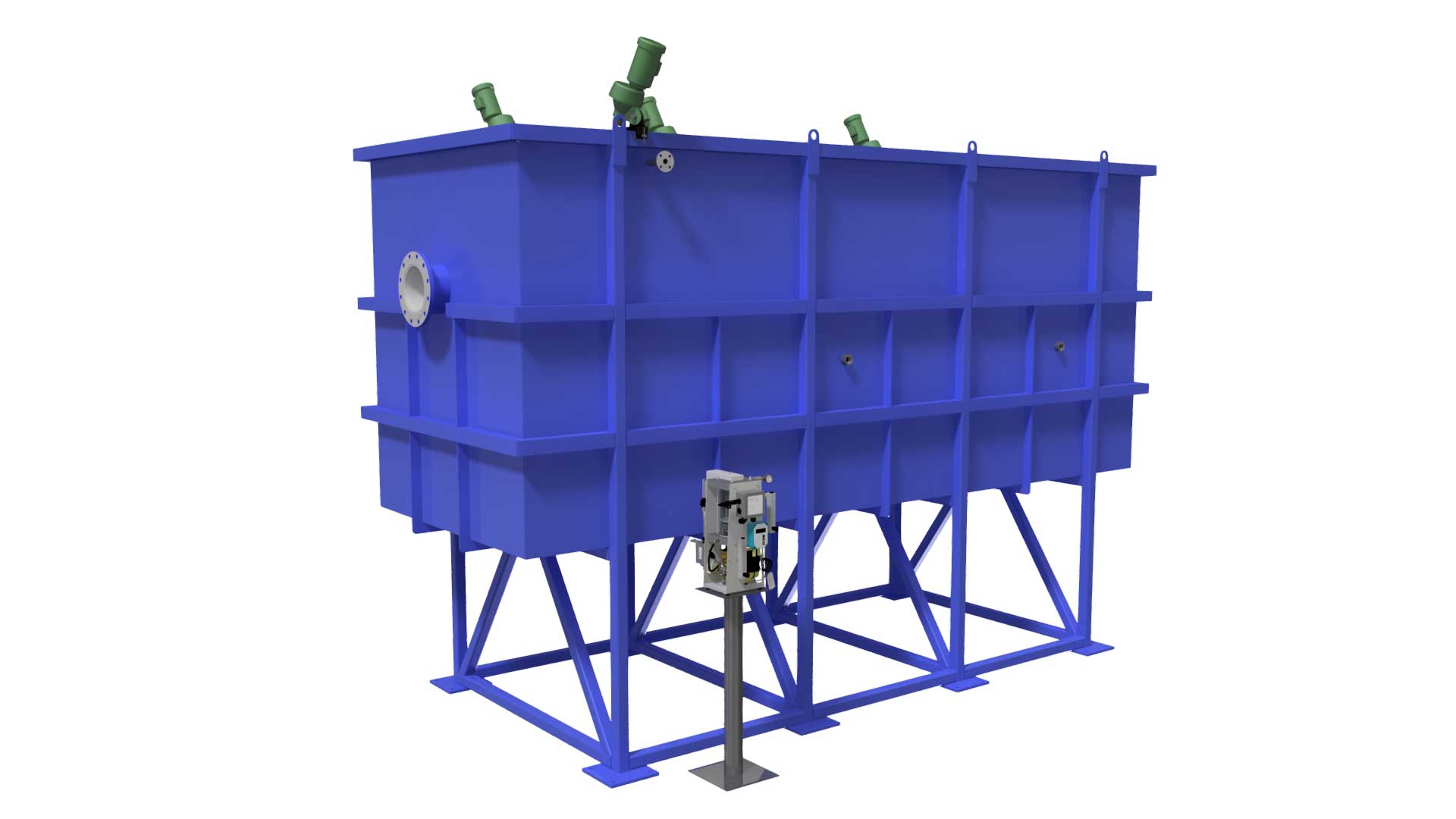

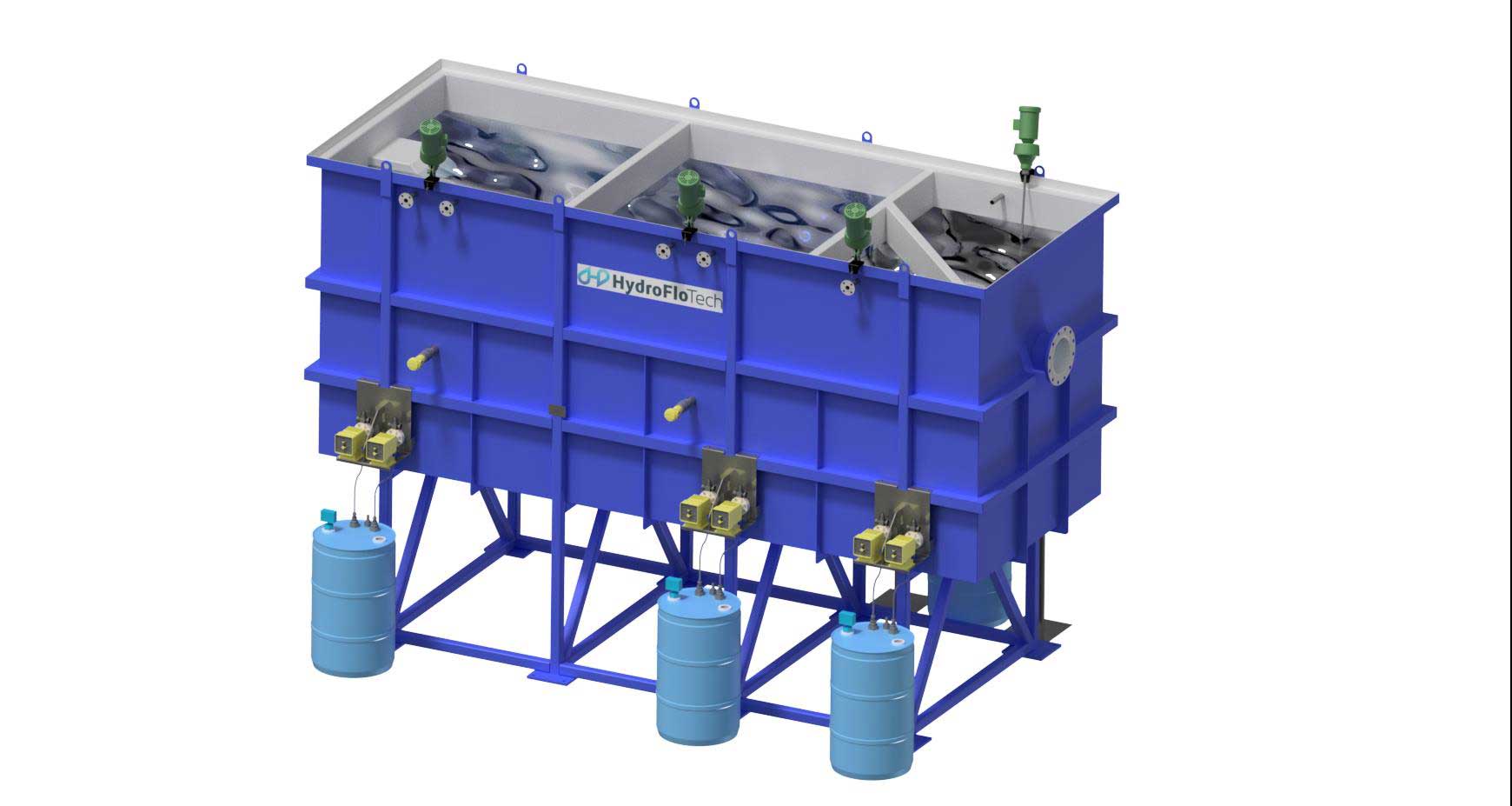

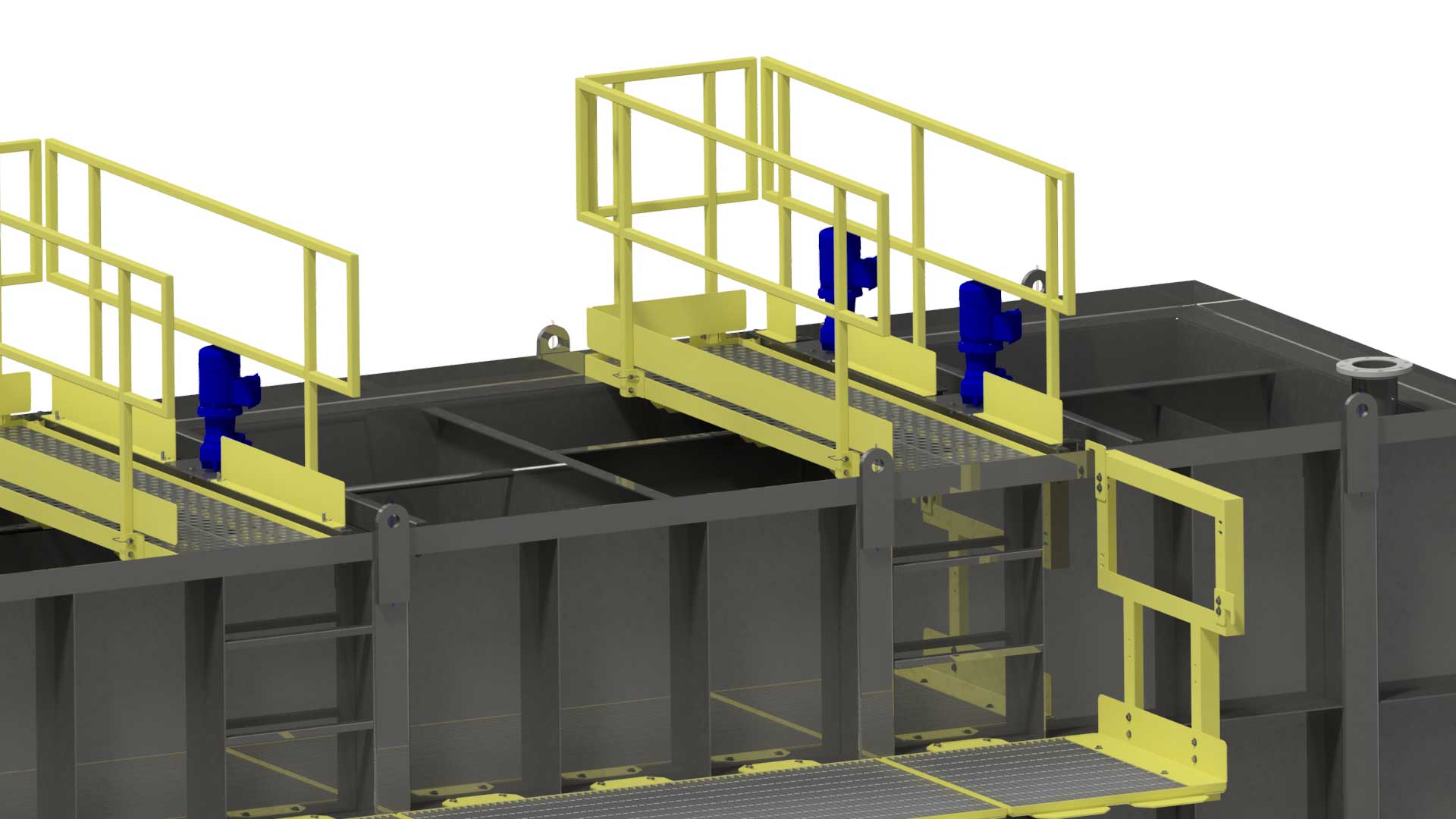

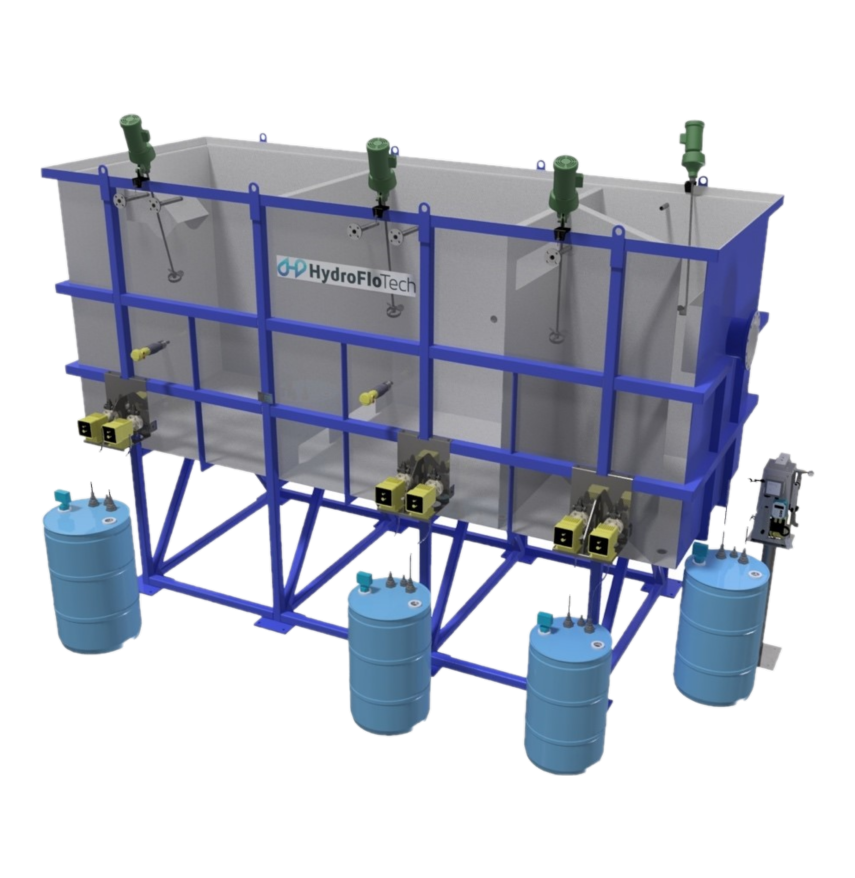

Chemical Pre-Treatment System

Standard Features

- Epoxy coated ASTM A-36 carbon steel tank

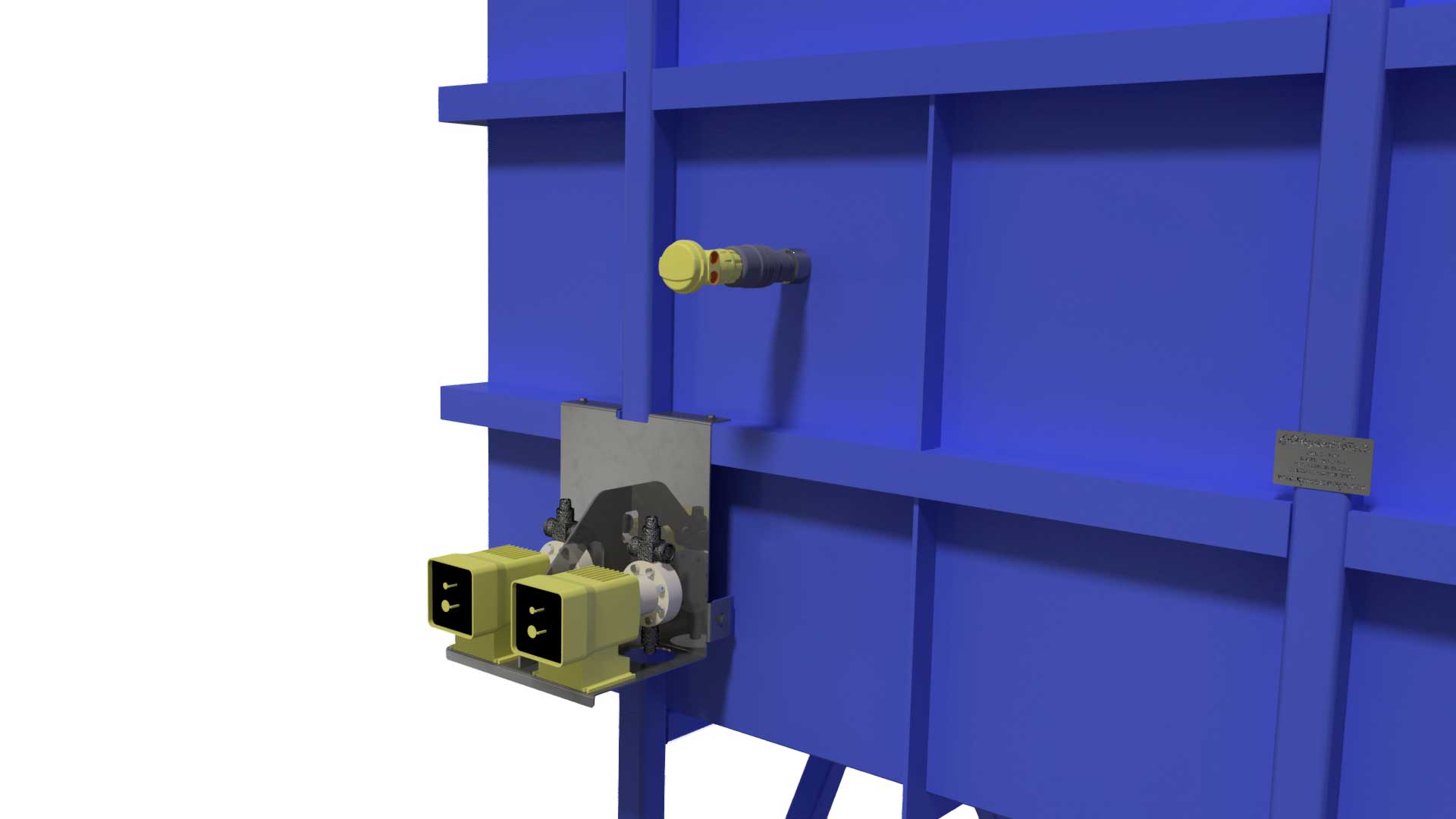

- Two stage (coagulant (flash), polymer (floc)) dosing systems

- Three stage (ph adjust, coagulant (flash), polymer (floc)) dosing systems

- Four stage (pH adjust (coarse), pH Adjust (fine), coagulant (flash), polymer (floc)) dosing systems

- Fully automated dosing and mixing based on flowrate

- Gravity based systems

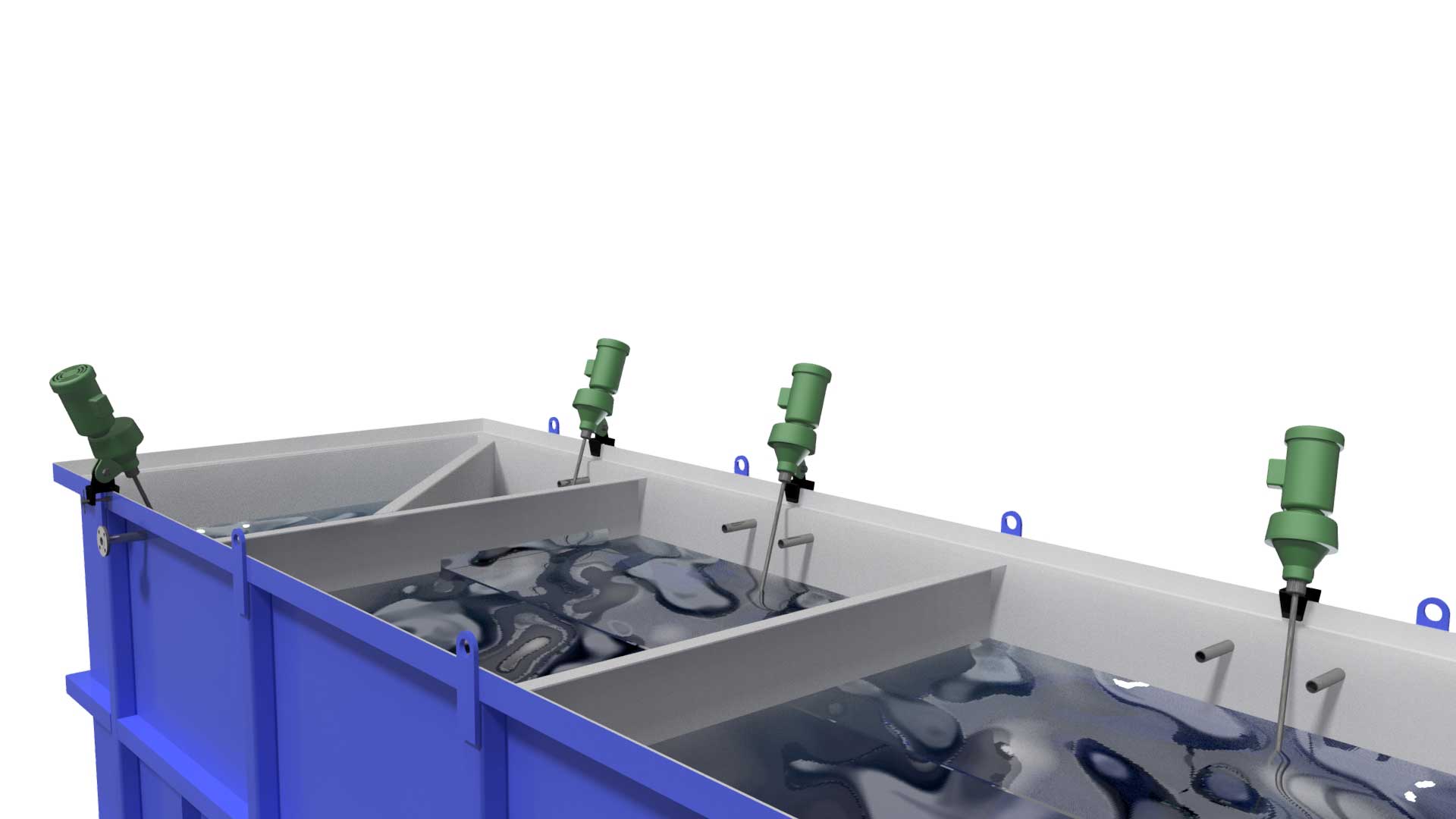

- Chambers are sized for the appropriate retention times

Available Options

The ChemiSep Pre-treatment Systems create particles of sufficient mass that can rapidly settle in a clarifier or of a mass capable of entraining bubbles (from a DAF) in order to float easily. If the resulting “pin floc” particles tend to sink, HydroFlotech recommends using clarifiers and if the resulting “pin floc” float or are buoyant neutral, then HydroFloTech recommends using a DAF to float those particles to the top of a separation chamber.

Additionally, chamber retention times are very important to ensure reaction completion prior to the next chamber. Not all chambers are the same. Residence times are dictated by the task. For example, pH adjustment may need a retention times of 10-15 minutes, coagulation dosing may need a retention times of 2-5 minutes and polymer dosing may need a retention times of 2-5 minutes.

One / Two stage (pH Adjustment):

pH adjustment may be required for certain specific applications in order to “un-dissolve” solids. pH Adjustment may also be required for breaking emulsion bonds. It’s first step is usually for pH elevation to precipitate solids, metals, demulsify oils, and to coagulate solids. Most coagulants, organic and inorganic tend to work better at elevated pH ~8.

Coagulant (flash) Dosing:

In this stage, “pin floc” is created. It is the stage where reaction first becomes visible to the naked eye by forming tiny pin head sized particle of precipitate. Coagulants typically fall into three categories, Iron Fe based typically used for metals applications, Aluminum or Alum (Al2SO4) based for oily based applications and high performance blends of various other types.

If metals are present and need to be coagulated, they must be precipitated first using sodium hydroxide at an elevated pH. Different metals prefer different pH levels

Polymer (floc) Dosing:

This stage is for the “gluing” of the floc formed in the previous stage. Floc is a special long chain polymer of either anionic or cationic charge that is used to agglomerate the “pin floc” created in the preceding stage. The pin floc will contain precipitated metals and/or demulsified oils and solids. Pin floc can be somewhat fragile and is best mixed with a variable speed mixer with operator control. If the floc is seen to break apart then the mixer is slowed to maintain mixing but not break the floc apart. Floc is important as it completes the process of creating sufficient mass to either be settled in a HydroFloTech Clarifier or floated in a HydroFloTech DAF.

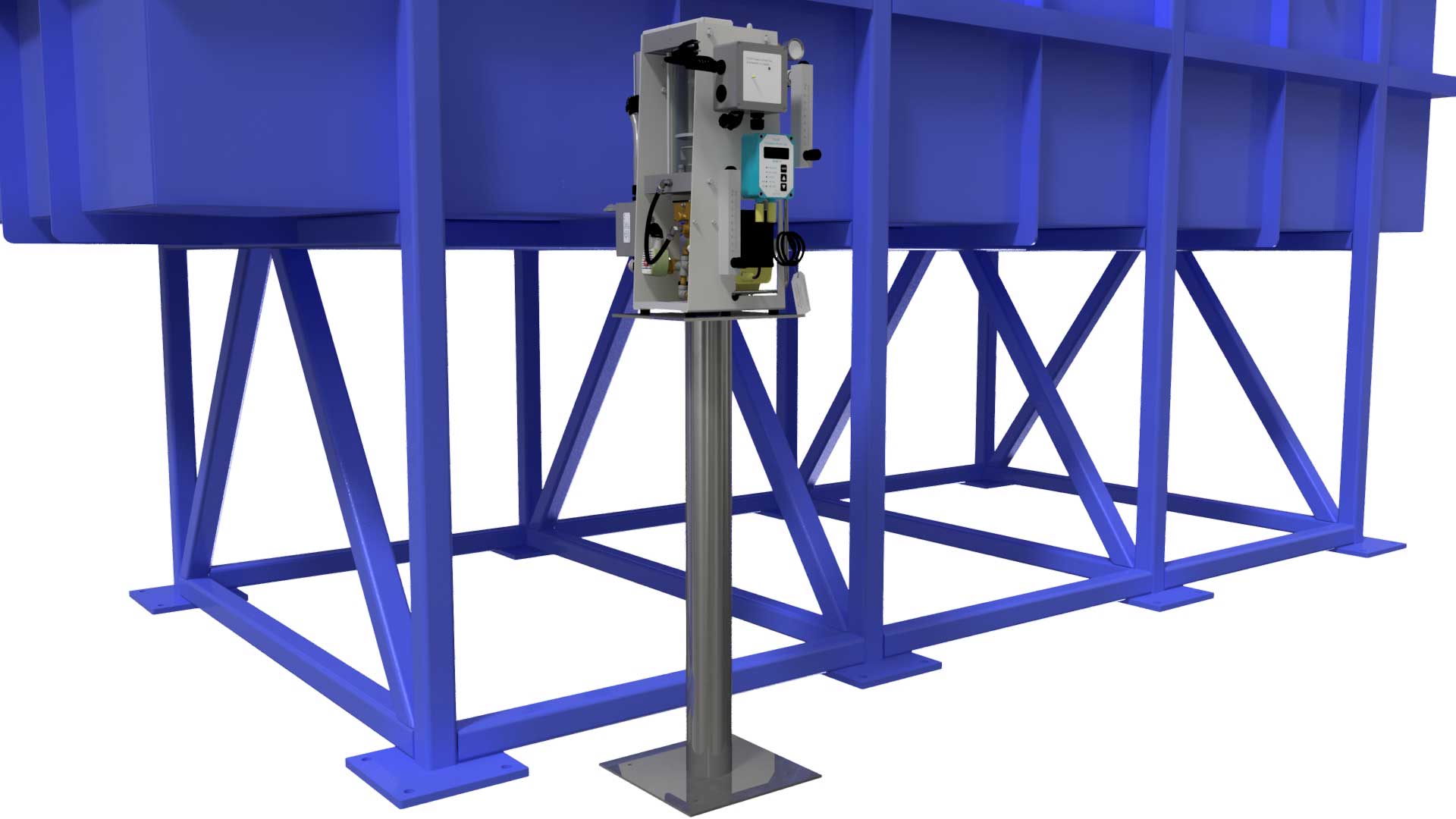

Control Package:

All ChemiSep systems are fully automated. Control packages (depending on your specific requirements) are available in either basic relay logic control, or a fully state of the art PLC with touch screen HMI and our sophisticated treatment algorithms. The relay logic controls package allow basic reconfiguration of the original system settings, while the PLC based package allows maximum flexibility to change the process parameters, as well as tight control that minimizes chemical usage. All enclosures are NEMA 4x.