EconoSep

Standard Features

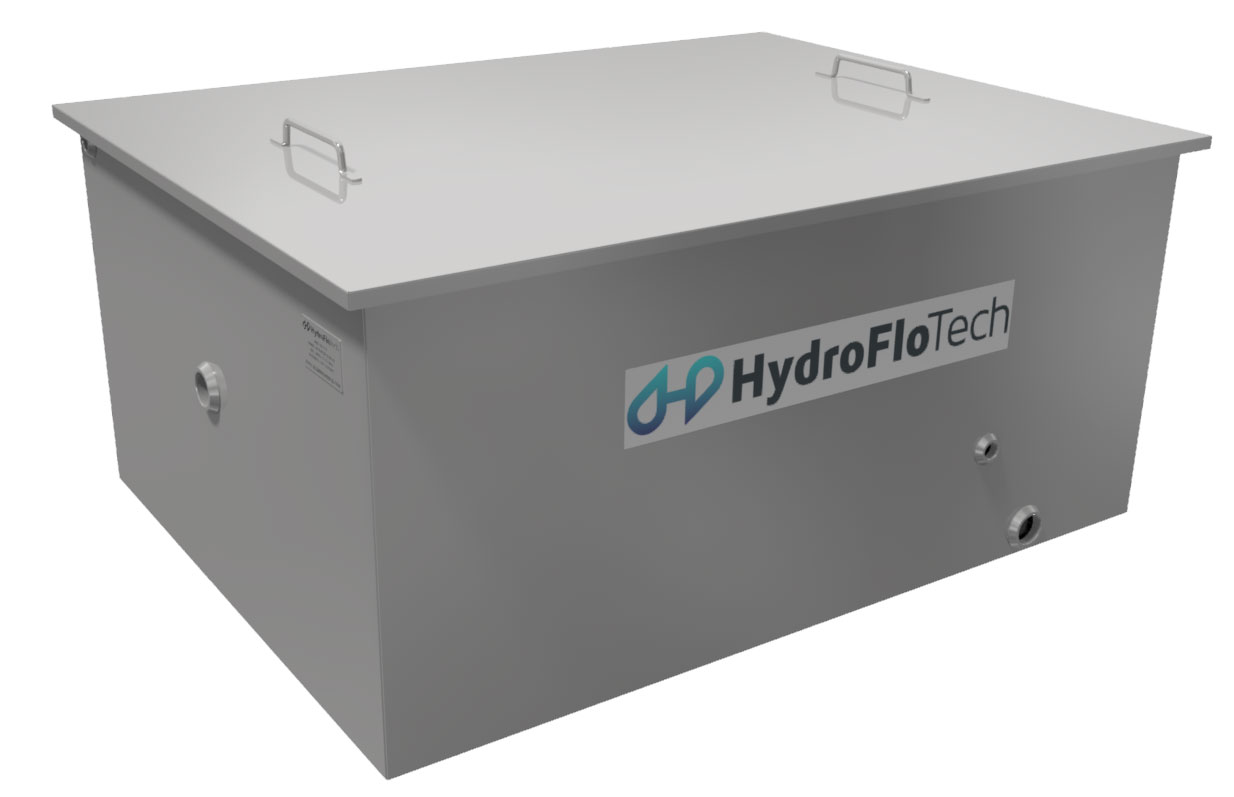

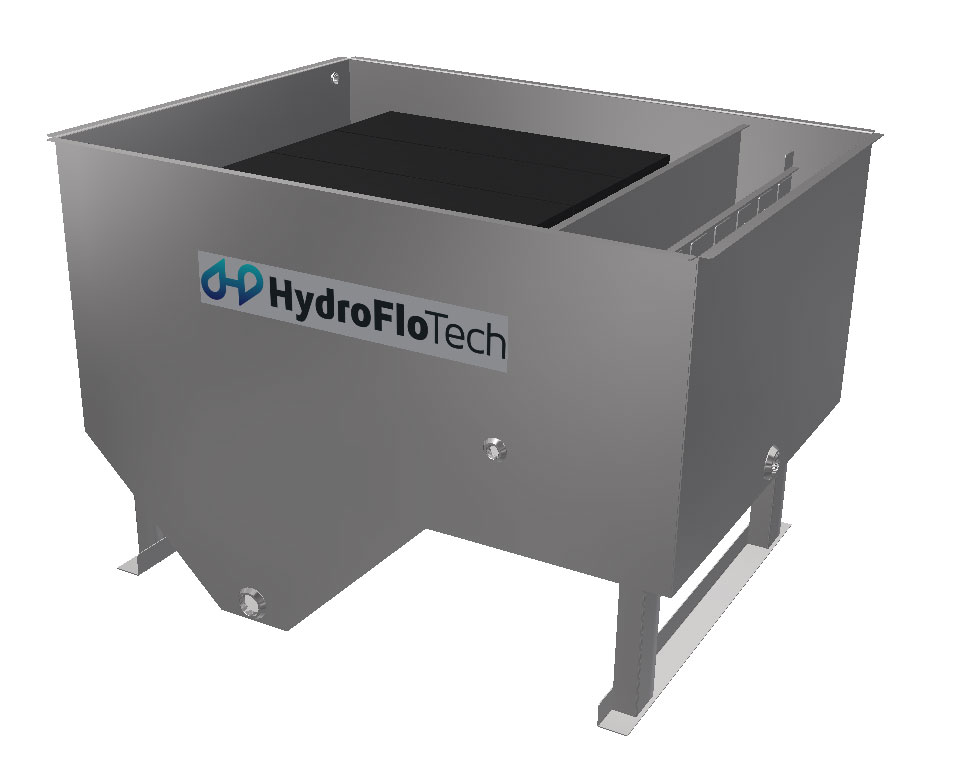

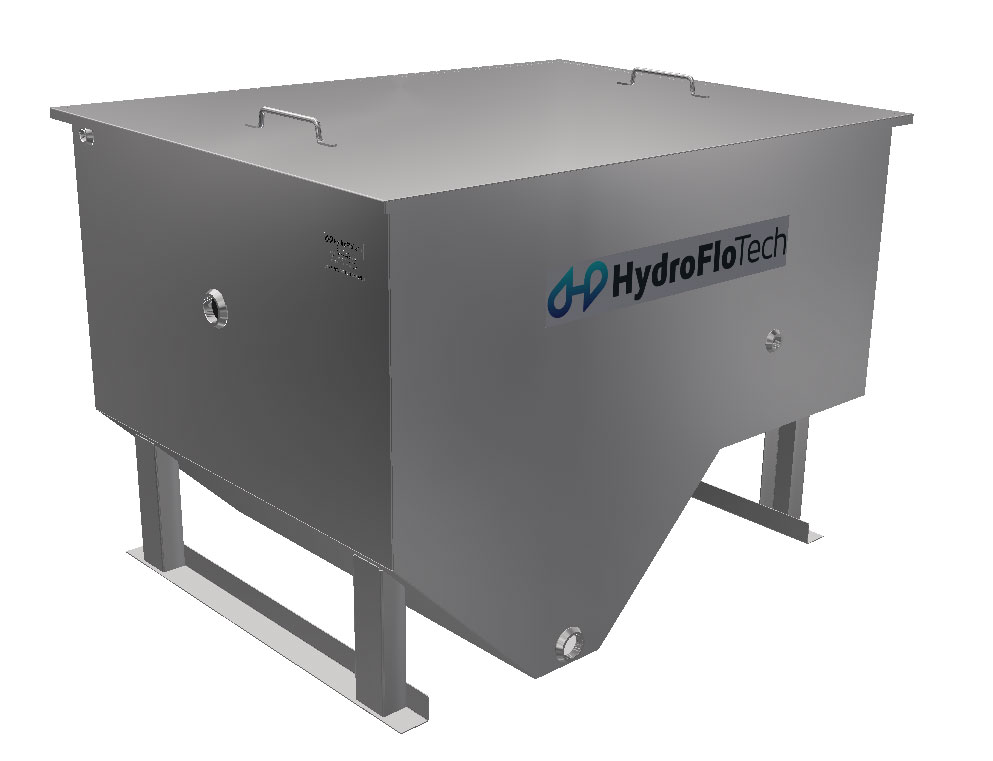

- 304 stainless steel tank

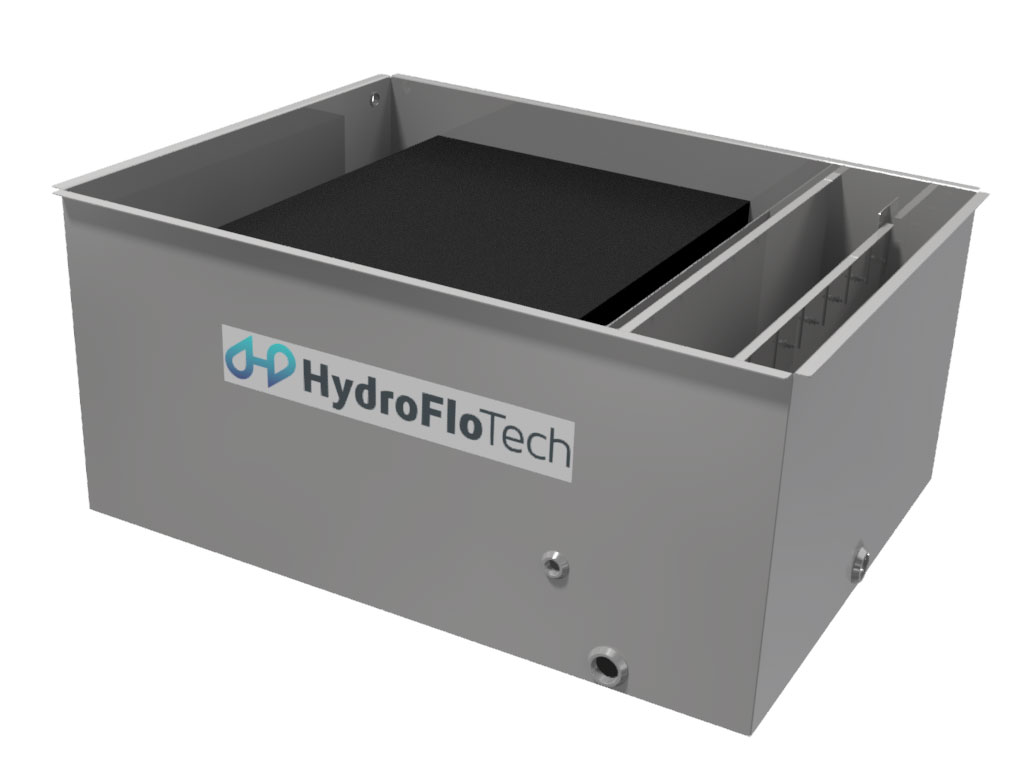

- Proprietary DynaPacTM hi-density PVC coalescing media

- Influent dispersion baffle

- Oil retention baffle specifically designed to enhance the performance of the DynaPacTM media

- Adjustable effluent weir system

- Removable lid assembly

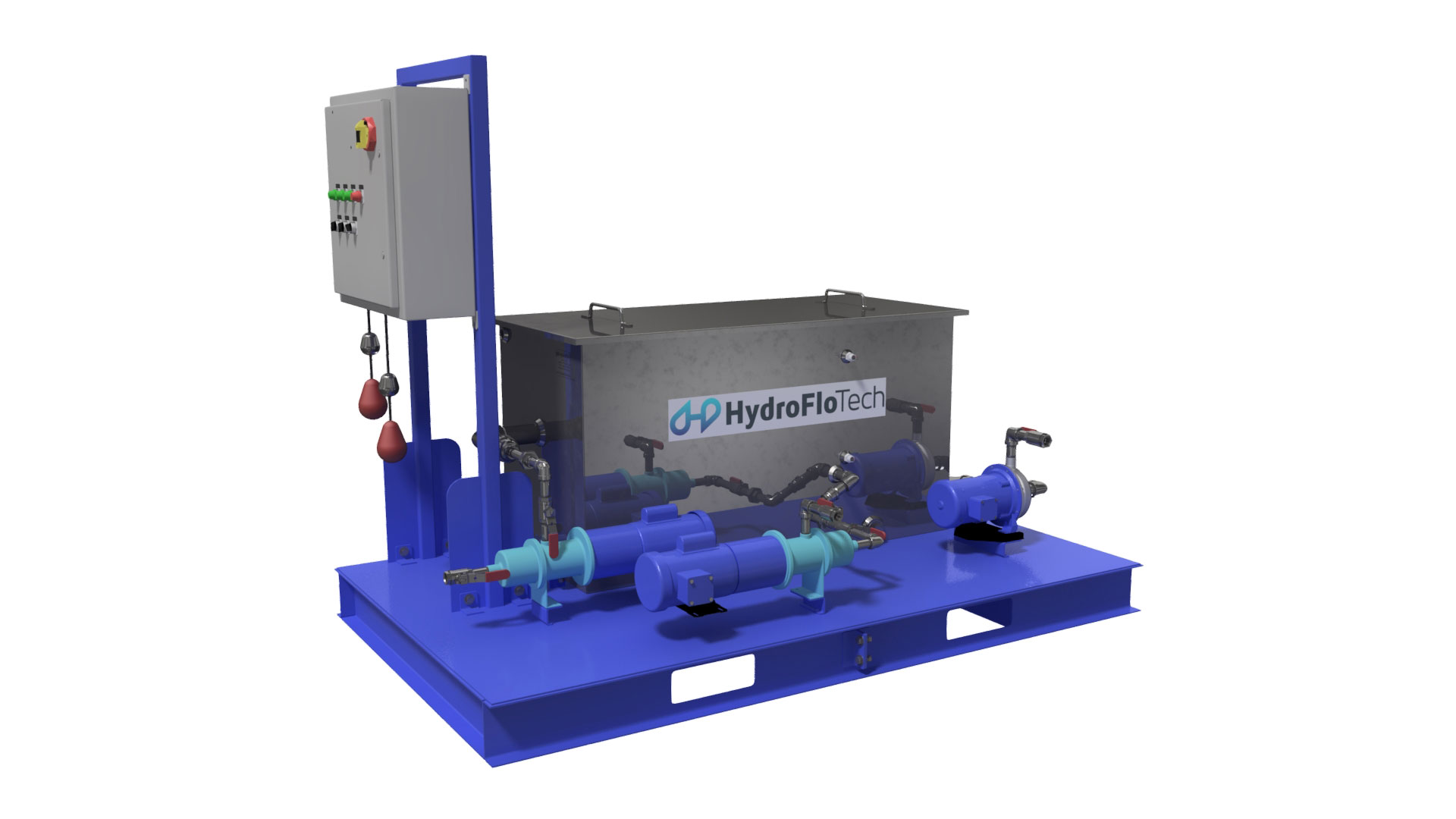

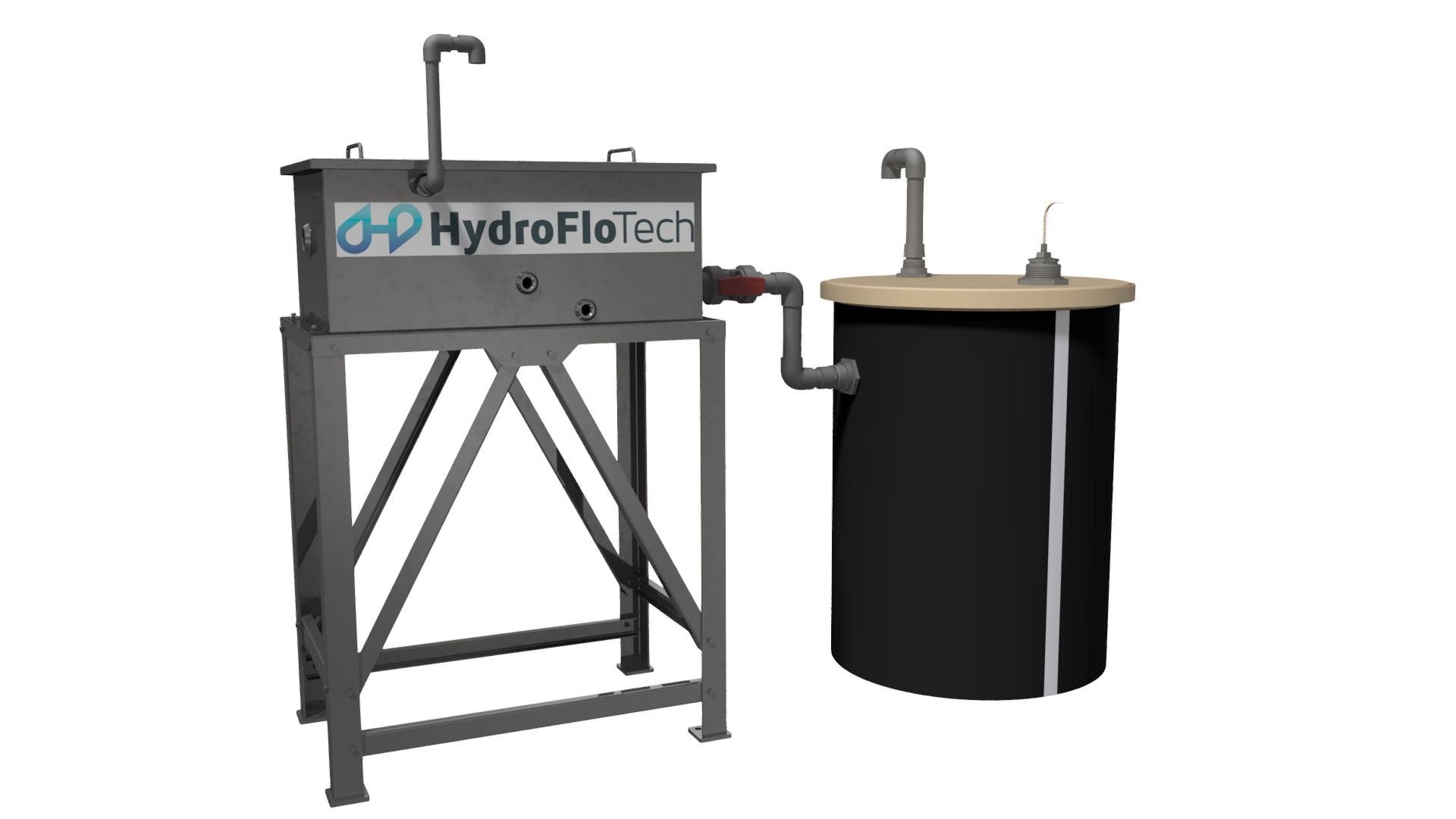

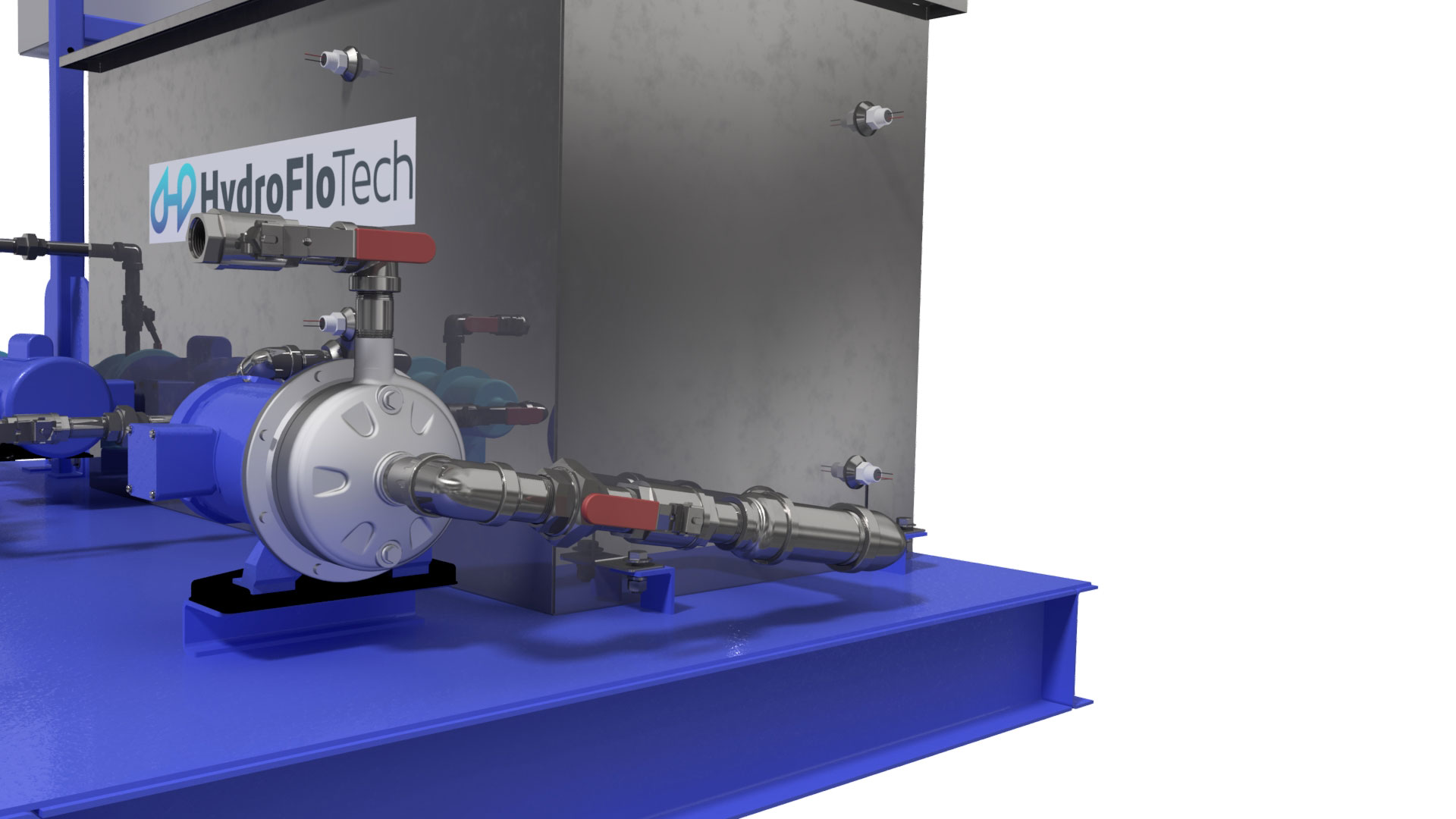

- Seamlessly integrates with other HydroFloTech wastewater products

Available Options

There are many considerations to be taken into account when designing an enhanced gravity oil water separator. The following needs to be taken into account as a minimum:

- Inlet flow distribution

- Length to height to width ratios (for proper overall flow distribution)

- Cross sectional velocities (actual, not nominal)

- Laminar flow conditions

- DynaPac™ Cross Corrugated coalescing media or parallel plate media “Reynolds” calculations (for quiescent flow distribution)

- Effluent flow distribution

- Total projected surface area

These basic design considerations all contribute to the complete utilization of the separation media. If followed propertly, the results will be consistent, equal flow distribution through the separation chamber and the media pack. These are the earmarks of a thoughtful, wholly engineered, fully developed oil/water separator design.

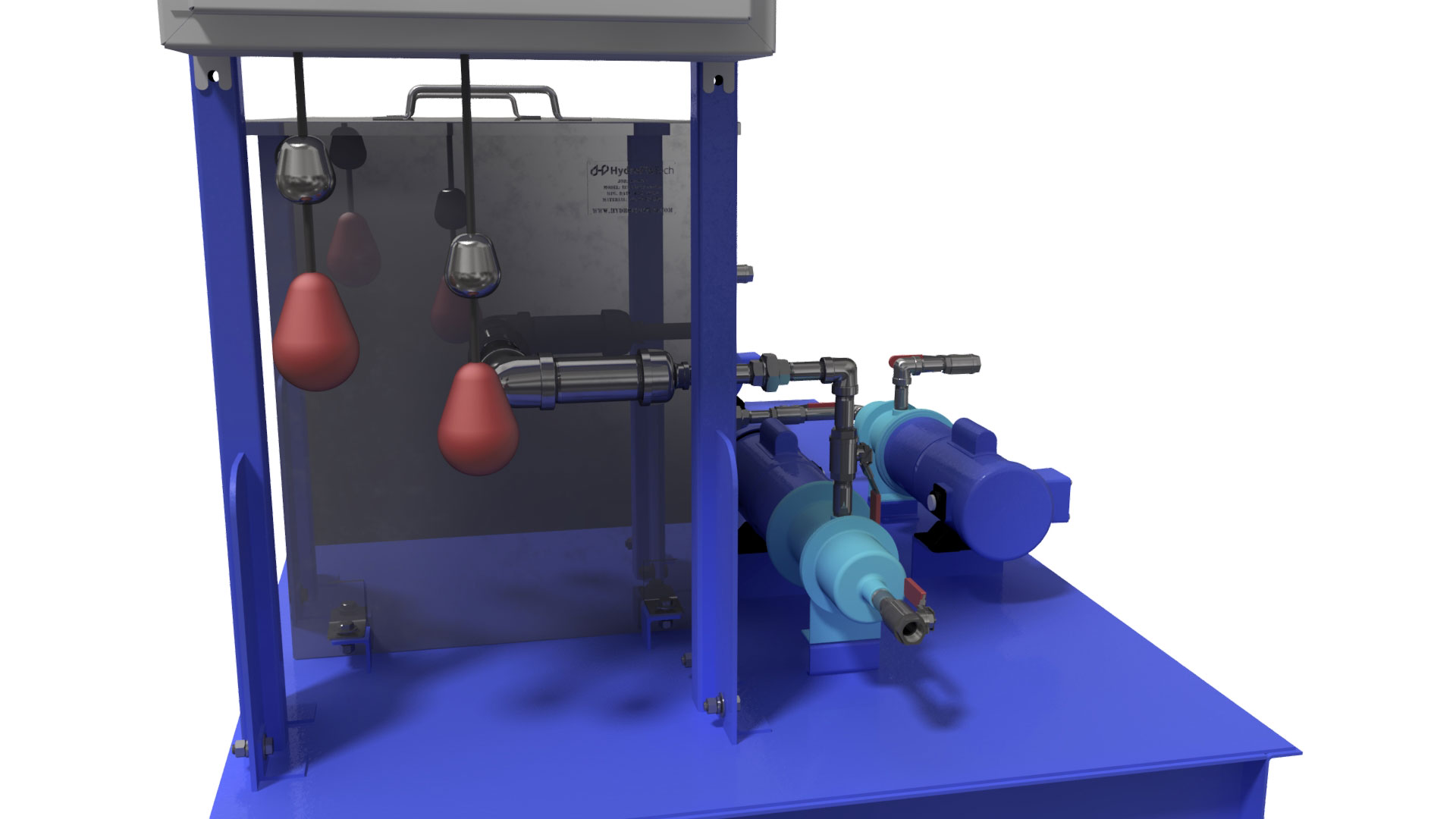

The separation cell is designed using elements of American Petroleum Institute’s publication 421 Feb. 1990 “Design of Oil-Water Separators” to ensure the best possible use of particle rise rate performance. The separation cell is a rectangular flat bottom tank manufactured from 304 stainless steel with an effluent surface baffle, 304 stainless steel full width adjustable overflow weir, effluent collection chamber with flanged outlet nozzle and recycle suction port, and angled float beaching plate.

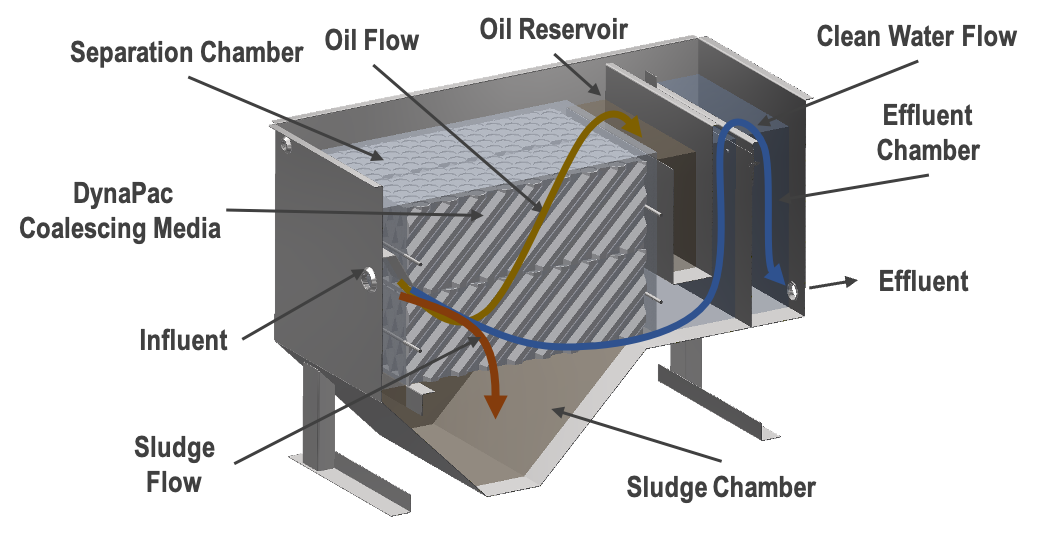

- Influent Diffusion Chamber

The flow enters the separator submerged, through an influent dispersion baffle. Dispersion across the depth and width of the DynaPac™ is to be achieved through the use of a non-clog diffuser. Heavy solids that fall out of suspension here are be channeled to the sludge collection chamber (for EconoSep “Hopper” ESH models only). - Separation Chamber

The Separation Chamber is designed to fit the exact amount of DynaPac™ cross corrugated coalescing media, sized for specific applications. Adequate space is to be left before and after the chamber to prevent short circuiting through the pack. DynaPacTM coalescing media is available in 0.5”, 0.75” and 1.25” sizes all in PVC, H-PVC, Polypropylene or 304 stainless steel. Depending on the correct sizing of the unit, this media (sized in cubic feet) provides the correct surface area (in square feet) for ideal separation. HydroFloTech oil water separator sizing sheets are a great resource to determine the size of media required by application (hyperlink). - Sludge Collection Chamber (for EconoSep “Hopper” ESH units)

The sludge collection chamber is located directly beneath the coalescing media pack and provide ample storage capacity for the settled sludge. - Oil Reservoir

The oil discharge port is located adjacent to the separation chamber. As the oil floats and rises to the top of the DynaPacTM media pack in the separation chamber, the oil retention baffle in the oil reservoir captures this separated oil. - Effluent Chamber

The aqueous phase leaving the DynaPac™ shall pass under the oil reservior and up over the adjustable 304 stainless steel effluent weir, which shall maintain the liquid level throughout the separator. - Removable Lids

The entire separator also includes a 304 stainless steel lid with handles for easy access. - Coalescing Media

The DynaPacTM coalescing media pack shall be fabricated of oleophilic cross corrugated coalescing media manufactured by HydroFloTech. Media is available in PVC, H-PVC, Polypropelene and 304 stainless steel.

| EconoSep™ Oil Water Separator – Model Specifications | ||||||||

| MODEL # | FLOW RATE (GPM) | UNIT DIMENSIONS | CAPACITY (US Gallons) | OPERATING WEIGHT (lbs.) | ||||

| Length | Width | Height | Overall Unit | Oil Reservoir | Effluent Chamber | |||

| (L) | (W) | (H) | ||||||

| ES-01 | 0 – 5 | 43” | 15” | 19” | 26 | 2 | 5 | 337 |

| ES-02 | 10 – 1 | 43” | 27” | 19” | 51 | 4 | 10 | 601 |

| ES-04 | 20 – 5 | 55” | 27” | 19” | 69 | 4 | 10 | 769 |

| ES-08 | 9 – 40 | 57” | 27” | 31” | 143 | 9 | 25 | 1,531 |

| ES-12 | 18 – 50 | 57” | 39” | 31” | 214 | 14 | 38 | 2,226 |

| ES-16 | 26 – 70 | 57” | 51” | 31” | 286 | 19 | 51 | 2,916 |

| ES-20 | 35 – 90 | 57” | 63” | 31” | 359 | 24 | 64 | 3,621 |

| ES-24 | 40 – 100 | 59” | 51” | 43” | 442 | 28 | 92 | 4,440 |

| ES-30 | 45 – 125 | 59” | 63” | 43” | 553 | 36 | 115 | 5,503 |

| ES-36 | 50 – 150 | 71” | 51” | 43” | 547 | 28 | 92 | 5,399 |

| EconoSep™ “Hopper” Oil Water Separator – Model Specifications | ||||||||

| MODEL # | FLOW RATE (GPM) | UNIT DIMENSIONS | CAPACITY (US Gallons) | OPERATING WEIGHT (lbs.) | ||||

| Length | Width | Height | Unit | Oil Reservoir | Effluent Chamber | |||

| (L) | (W) | (H) | ||||||

| ESH-01 | 0 – 5 | 43” | 15″ | 24″ | 28 | 2 | 5 | 360 |

| ESH-02 | 10 – 1 | 43” | 27″ | 24″ | 56 | 4 | 10 | 655 |

| ESH-04 | 20 – 5 | 55” | 27″ | 29″ | 87 | 4 | 10 | 955 |

| ESH-08 | 9 – 40 | 57” | 27″ | 41″ | 161 | 9 | 25 | 1,713 |

| ESH-12 | 18 – 50 | 57” | 39″ | 41″ | 242 | 14 | 38 | 2,492 |

| ESH-16 | 26 – 70 | 57” | 51″ | 41″ | 323 | 19 | 51 | 3,272 |

| ESH-20 | 35 – 90 | 57” | 63″ | 41″ | 405 | 24 | 64 | 4,060 |

| ESH-24 | 40 – 100 | 59” | 51″ | 53″ | 479 | 28 | 92 | 4,828 |

| ESH-30 | 45 – 125 | 59” | 63″ | 53″ | 599 | 36 | 115 | 5,976 |

| ESH-36 | 50 – 150 | 71” | 51″ | 59″ | 626 | 28 | 92 | 6,158 |

| Equipment Designing Data & Sizing Sheet Calculations | Drawings | Specifications | Installation, Operation & Maintenance Manual |

|---|---|---|---|

| Oil/Water Separator Theory of Operation | EconoSep General Arrangement Drawing | EconoSep Engineering Specification | EconoSep Standard IO&M |

| Oil/Water Separator Design Parameters | EconoSep “Hopper” General Arrangement Drawing | “Common” Engineering Specification |

EconoSep “Hopper” Standard IO&M |

| EconoSep Sizing Spreadsheet | General IO&M Considerations Applicable to all HydroFlo Manufactured Equipment |